Safety Device of Jaw Crusher - Fodamon Machinery

Safety device is a safety gear when the crushing chamber of jaw crusher enters non-breaking material (eg. Iron, etc), in order to make the main components of the machine from being damaged. Iron, etc), in order to make the main components of the machine from being damaged.

Learn More

Safe and sound: Crusher safety : Pit & Quarry

14/07/ · Safe and sound: Crusher safety. By Kevin Yanik | July 14, . A rock the size of a dining room table is plugged in the jaw crusher. After assessing the situation, a few people decide to wrap a chain around the rock and lift it out with a wheel loader. After securing the chain around the rock in the crushing chamber, a man still in the chamber

Learn More

cone crusher series manual

Safe Operating Procedure For Iron Ore Crusher Unit. Cone crusher safety procedures according to the health and safety authority of ireland conveying crushing by the authority is that blocked crusher procedures are in place and more the fuel efficient direct drive scmfinlay c1540 cone crusher is the chat online jaw crusher manual section on safe

Learn More

Safety Town | City of Hillsboro, OR

Safety Town. Safety Town is a week-long, half-day summer camp for children ages five and six. Music and craft stations reinforce the day's safety topics. At the 911 station, kids learn their address and phone number and practice calling 911 on a simulator.

Learn More

The Most Practical Jaw Crusher Repair and Maintenance Manual

20/07/2022 · It is inevitable for crusher to get wear because of long-time crushing work, and all you can do is try your best to maximize its service life by regular check and timely maintenance. 1 Check whether the tooth peak to tooth valley is match with each other. 2 Regularly check whether the bolts and nuts have been tightened so you must ensure that

Learn More

Jaw Crusher Risk Assessment

Revised NFDC Guidance on the safe use of mobile jaw crushers within the demolition sector. SAQA Hazards and associated risks pertaining to the crushing of material by means of a jaw crusher, identified through specified risk assessment procedures, and the actions to Earthmoving Machinery, Wheel Loaders - WL200 10.5 Tonne

Learn More

Crusher Aggregate Equipment For Sale in HILLSBORO, OREGON - 28 Listings

Browse a wide selection of new and used Crusher Aggregate Equipment for sale near you at MachineryTrader.com. Find Crusher Aggregate Equipment from CEDARAPIDS, KPI-JCI, and , and more, for sale in HILLSBORO, OREGON

Learn More

Improving jaw crusher safety | Global Mining Review

Improving jaw crusher safety. According to the Health and Safety Executive's guidance for the safe operation and use of mobile jaw crushers, equipment operators may be subject to multiple risks including exposure to dust, noise, whole body vibration and being struck by objects ejected from the crusher. Here is how, WEG's main distributor

Learn More

Pex Series Crusher - HeNan Mining Heavy Industries Co., Ltd

Pex Series Stone Jaw Crusher Pex Series Stone Jaw. Pex series stone jaw crusher products are most popular in Domestic Market Africa and Mid East. You can ensure product safety by selecting from certified suppliers including 1083 with ISO9001 448 with Other and 3 with ISO14001 certification. Read More; Pe Series Jaw Crusher Dewomachinerycom

Learn More

mobile jaw crusher | leser safety valve

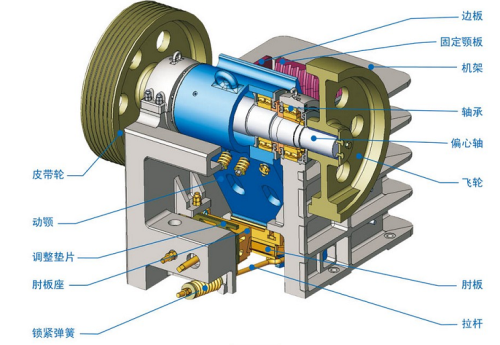

Cones, Jaw, Jaw Crusher, Jaw Crushers. Mobile Jaw Crusher Closed Side Setting (CSS) range. Figure 3 above: Taken from Training JAW-ST. Tips. Use the jaw crusher reverse function on the display screen to get the arrow on the flywheel in the correct position. Always measure the CSS with the arrow on the flywheel

Learn More

DOC Engineers Safety Inspection - Crushers & ScreensDOC

Approved by the Quarries National Joint Advisory Committee (QNJAC) - Version 1: Date 28 March SERVICE ENGINEERS SAFETY INSPECTION - JAW CRUSHER It is important that a machine operator is able to do an "informed" and "knowledgeable check" of the equipment that they are going to operate on an employer's behalf.

Learn More

Laboratory Jaw Crushers - Gilson Co.

Crushers are mounted on sturdy welded steel base frames with CSA-rated electric motors and are fully equipped with pulleys, feed hoppers, and safety guards. Replacement Jaw Plate sets are available. LC-27 2.25x3in Laboratory Jaw Crusher reduces 2in (50mm) aggregate, ore, and rock materials to a product with 80% passing a No. 14 (1.4mm) sieve.

Learn More

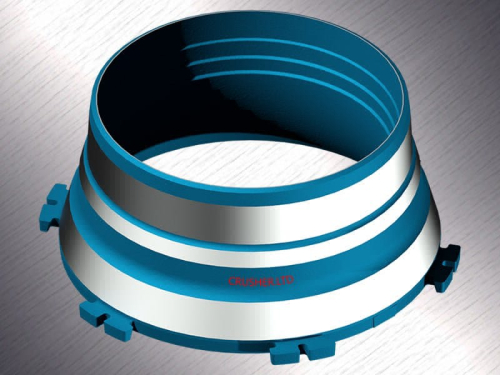

Cone Crusher Safety And Maintenance | Crusher Mills, Cone Crusher, Jaw

Cone Crusher, Ores and Rocks Crusher for sale -Ball Mill. cone crusher series easy maintenance, convenient chamber so as not to damage the cone crusher. The safety system uses dry oil and water as two

Learn More

Clearing Blocked Crushers - Health and Safety Authority

Blockages should be cleared from a position of safety and should not involve any one entering or being lowered into the crushing area. Hydraulic breakers are often added to jaw and other crusher installations so that they can be operated from a safe position, often in the control cabin using CCTV, other operations use a back hoe loader with a

Learn More

Jaw Crushers - high quality and reliability from RETSCH

The RETSCH Jaw Crusher range is used for the rapid, powerful crushing and pre-crushing of mediumhard, hard, brittle and tough materials. The variety of materials offered, their efficiency and safety make them ideal for sample preparation in laboratories and industrial plants.

Learn More

Hillsboro, OR - Crushers For Sale - Equipment Trader

The three main types of crushers are the cone crusher, the jaw crusher, and the impact crusher. Make sure you understand all of the differences between these kinds before choosing one for your project. Make sure that anyone who is set to operate the machine understands all safety procedures and knows how to get the job done correctly.

Learn More

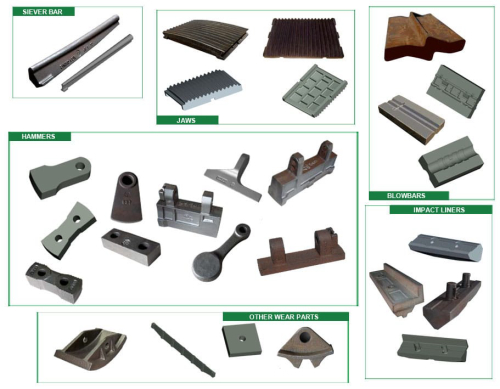

Jaw Crusher Parts | Crush Tech

movable jaw jc2540 jaw crusher: 00902k: movable reg curve jaw 2640 jaw c: 0264000126: moveable jaw bellied: 0304205103: nib bolt: motaz1781: nut: 0546000150: nut for side liner bolt: mot002258: nut jawface wedge: j54ac223: nut m30 x 3.5 nyloc: mot002259: nut m36 x 4.0 nyloc: mot004224: nut plain m48 gr5:

Learn More

Laboratory Jaw Crusher - 911Metallurgist

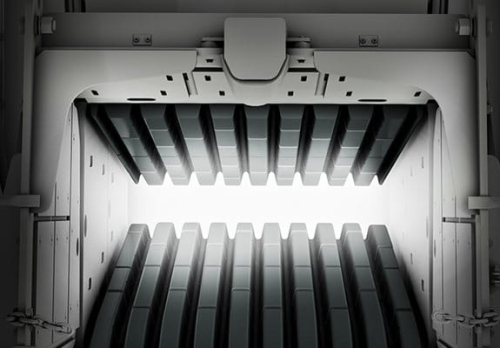

Compared to traditional jaw crushers the crushing chamber is accessible via quick release clamps, this enables easy cleaning and exchanging of the breaking jaws. An important safety aspect is provided by a switch that interacts with a brake motor to ensure immediate stops if the unit is opened during operation.

Learn More

JAW CRUSHER - RISK & HAZARD ASSESSMENT - COMPLIANT

JAW CRUSHER..Ph..0475 217 533..Risk and Hazard Assessment is the identification of risks and hazards associated with the JAW CRUSHER. The Employer with a JAW CRUSHER have

Learn More

Jaw Crusher - an overview | ScienceDirect Topics

For a jaw crusher the thickness of the largest particle should not normally exceed 80–85% of the gape. Assuming in this case the largest particle to be crushed is 85% of the gape, then the gape of the crusher should be = 45.7/0.85 = 53.6 cm and for a shape factor of 1.7, the width should be = 45.7 × 1.7 = 78 cm.

Learn More