design and operations challenges of a single toggle jaw crusher

Productivity of the crusher can be improved upon by increasing the eccentricity of the eccentric shaft, use of reversible jaws, bush bearing

Learn More

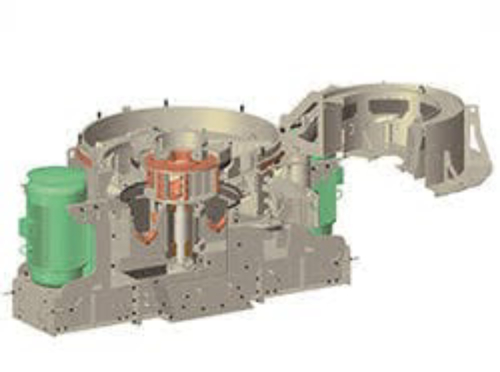

Eccentric Shaft JAW CRUSHER

Eccentric Shaft – Construction Crushers Training and Back Figure 4-56. Support shaft, removal and installation. Up TM-5-3820-233-12-1 Crusher Jaw Diesel Engine Driven Semitrailer

Learn More

CONCEPTUAL DESIGN FOR A PROTOTYPE FUEL

The first major equipment item is an overhead eccentric jaw crusher. (primary crusher) designed for initial crushing of the entire HTGR fuel.

Learn More

MEKA Jaw Crushers - Berkshire Engineering Supplies

MEKA Jaw Crushers are designed for cost-efficient primary reduction of A very large eccentric shaft and four large spherical roller bearings ensure the

Learn More

The Working Principle Of A Jaw Crusher - Editors Top

25/12/ · The bigger the chamber, the more powerful the jaw crusher. The crushing process can be basically explained as a process where the materials are sandwiched between two jaw plates. The movable jaw plates squeeze and crush the materials into several small pieces. There are two main types of jaw crushers: double toggle and overhead eccentric jaw

Learn More

V-C Jaw Crusher - VERTEX

In order to ensure that the equipment can work efficiently when crushing hard materials, the core rotating components of the jaw crusher is made of parts such as a casted high-quality moving jaw, forged large eccentricity heavy-duty eccentric shaft, casted high rotational inertia flywheel and monobloc casted high strength steel bearings box.

Learn More

mj series jaw crushers

Single Toggle MEKA Jaw Crusher is designed for applica- Large diameter forged alloy steel eccentric shaft,.

Learn More

Jaw Crushers - Prime Machine, Inc

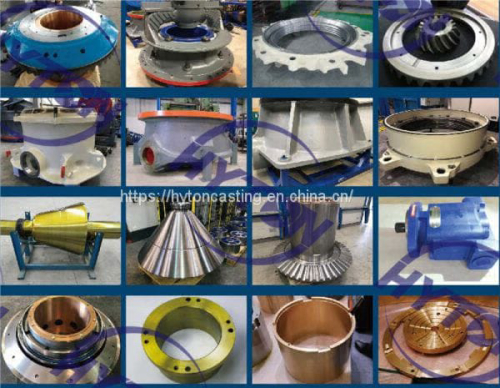

Machining babbitt bearing for Jaw crusher. Eccentric shaft jaw crusher being welded. Eccentric shaft Jaw Crusher prep for sub arc weld shaft. jaw crusher toggle

Learn More

eccentric shaft for jaw crusher | zbe 101 schneider electric

V-C Jaw Crusher. In order to ensure that the equipment can work efficiently when crushing hard materials, the core rotating components of the jaw crusher is made of parts such as a casted high-quality moving jaw, forged large eccentricity heavy-duty eccentric shaft, casted high rotational inertia flywheel and monobloc casted high strength steel bearings box.

Learn More

Jaw Crusher Eccentric Shaft | Crusher Spare Parts | GTEK

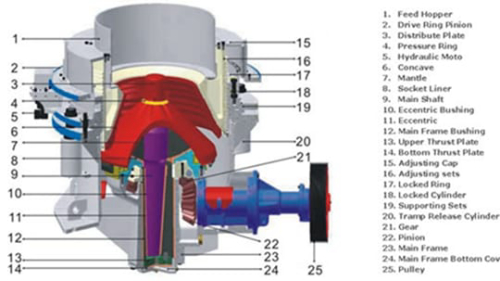

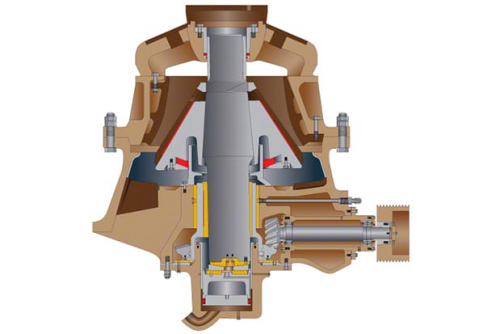

Description. Jaw Crusher Eccentric Shaft is installed on the top of the jaw crusher. It runs through the movable jaw, pulley and flywheel. All of them are connect with each other by the eccentric

Learn More

eccentric shaft design of jaw crusher

Mar 28, · Double-toggle jaw crushers. In a double-toggle jaw crusher, the moving crusher jaw is driven by the eccentric shaft that moves the front and rear

Learn More

B10 ECCENTRIC SHAFT jaw crusher eccentric shaft design

B10 ECCENTRIC SHAFT jaw crusher eccentric shaft design CN102561854A - Adjustable latch hook mechanism. Said adjustable bearing pin is an eccentric shaft. of Regulation sketch map that the present invention regulates pin 4 and adjustment cam A5, B10. GoTo Products | Bosch Rexroth USA. 4WEH16HD7X/O6EG24N9ETK4/B10.

Learn More

Eccentric shaft design of jaw crusher - Shanghai Clirik

The main shaft that rotates and has a large flywheel mounted on each end. Its eccentric shape moves the moving jaw in and out. Eccentric Shaft is machined out

Learn More

Development Design for Jaw Crusher Used in Cement Factories

The eccentric rotating drive shaft causes the movable jaw to oscillate crushing the aggregate against a fixed jaw. Jaw crushers are run on belt drives

Learn More

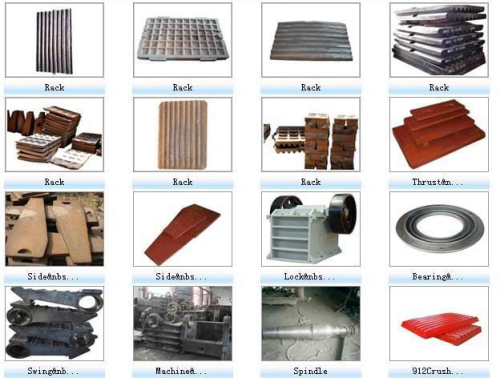

jaw crusher eccentric shaft | machine bearing bush mill

Jaw crusher movement is guided by pivoting one end of the swinging jaw. and an eccentric motion located at the opposite end. [4] The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws .For instance, a 22 x 30 jaw crusher has an opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" square.

Learn More

Jaw Crusher Eccentric Shaft

Crusher Eccentric Shaft-Crusher Eccentric Shaft Manufacturers . Min. Order: 1 Set FOB Price: US $4000-50000 / Set. Jaw Crusher-Forged heavy-duty eccentric shaft-The good Cavity Design

Learn More

Jaw Crusher Eccentric Shaft Design

Difference Between Single Double Toggle Jaw Crushers 2. Difference between single double toggle jaw crushers 2 a double toggle crusher has basically two shafts and two toggle plates the first shaft is a pivoting shaft on the top of the crusher while the other is an eccentric shaft that drives both toggle plates the moving jaw has a pure reciprocating motion toward the fixed jaw the crushing

Learn More

ROTOR 840 O-S BAR MKIII jaw crusher eccentric shaft design

The Flexifeed FF mantle features a patented design with a variable intake in the upper 485.0152-901, ROTOR 840 O-S BAR MKIII. brand spare inner bushing for mobile crushers trio jaw crusher for recycling clinker crusher hammer powder milling amp amp particle technology small hammer crusher.

Learn More

Eccentric Eccentric Shaft Of A Jaw Crusher-jaw Crusher

Industrial Solutions Jaw Crushers. Average throughput rate of singletoggle jaw crusher standard version tolerance 10 doubletoggle jaw crushers design doubletoggle jaw crushers are equipped with a doubletoggle system which is con trolled by a pitman that moves up and down under the influence of an eccentric shaft causing the toggle plates to alternately flex and

Learn More

Eccentric Shaft For Jaw Crusher - Precision Machine Shop

Eccentric Shaft For Jaw Crusher. December 26, 2018By: Molly Risak. No Comments. No comments yet. Sorry, the comment form is closed at this time.

Learn More

How to Design a Eccentric Shaft #124|Industrial design

27/09/ · #designwithajay #solidworksmechanical #tutorial #SolidWorks It is used most often in steam engines, and used to convert rotary motion into linear reciprocati

Learn More