Jaw Crusher Pdf | Crusher Mills, Cone Crusher, Jaw Crushers

Portable Screen- Vibrating Screens, Crushers . 3858 JAW CRUSHER An Astec company SPECIFICATIONS www.telsmith.com [email protected] (800) 765-6601 (262) 242-6600 PO Box 539 Mequon, WI 53092 The crusher product diagram pictured .

Learn More

C Series Jaw Crushers - RocketCDN

The first is the well-known traditional jaw crusher range that is designed for stationary as well Their simple design means fewer moving parts come into.

Learn More

PDF R Crusher Wear Parts Reference GuidePDF

This Guide has been developed to help Dealers personnel to expand their knowledge of Crusher Wear part options & terminology and help relay this information to end users in a clear and logical manner. The Guide is broken down into following sections : 1. Wear Parts Overview 2. Jaw Crusher Wear Parts 3.• Cone Crusher Wear Parts 4.

Learn More

JAW CRUSHER SERIES

Our jaw crushers are of the single-toggle type and feature a deep, symmetrical crushing chamber, a large feed opening for its size, and an ideal nip angle that

Learn More

PDF TECHNICAL NOTES 5 CRUSHERS - Mineral TechPDF

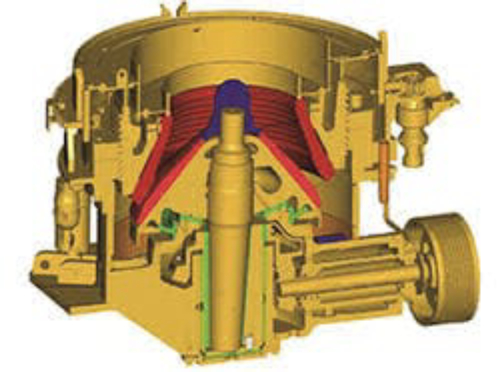

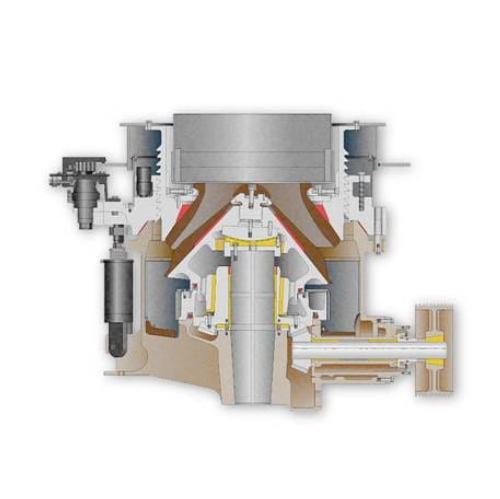

Jaw and gyratory crushers are used mostly for primary crushing. They are characterized by wide gape and narrow discharge and are designed to handle large quantities of material. The capacity of the crusher is determined by its size. The gape determines the maximum size of material that can be accepted.

Learn More

PDF CRUSHER PARTS & SERVICES - Hofmann EngineeringPDF

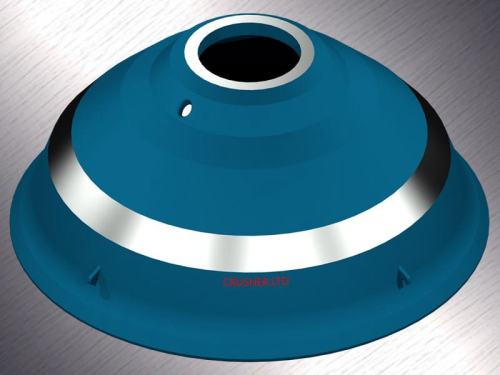

JAW CRUSHER COMPONENTS & WEAR LINERS ROLLS CRUSHERS - HARD FACED, WHITE IRON & SEGMENTED BEVEL GEARS CONE CRUSHER HEADS CRUSHER PARTS & SERVICES and refurbishment of worn parts. Extensive fabrication, heat treatment and machining departments can accommodate individual components up to 200 tonnes, allowing for a

Learn More

Jaw crushers - Thyssen Krupp

For these tasks thyssenkrupp Industrial. Solutions has in its range two types of jaw crusher, which differ in the kinematics of the swing jaw: single-toggle jaw

Learn More

PDF "Computer Aided Design of Jaw crusher"PDF

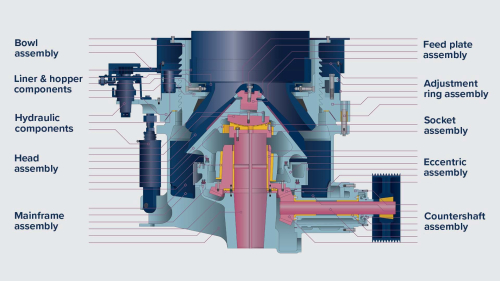

The mechanism of jaw crusher is based on the concept "crushing without rub ". Jaw crushers consist of two jaws. One fixed and the other reciprocating. The opening between them is largest at the top and decreases towards the bottom. The pitman moves on an eccentric shaft and swing lever swings on centre pin.

Learn More

CRUSHER PARTS & SERVICES - Hofmann Engineering

MAIN FRAMESNew and refurbishedMINERAL SIZERS SPIDERS & ANCILLARY COMPONENTS INTEGRAL MAIN SHAFTS, CORES & MANTLES JAW CRUSHER COMPONENTS & WEAR LINERS ROLLS CRUSHERS - HARD FACED, WHITE IRON & SEGMENTED BEVEL GEARS CONE CRUSHER HEADS CRUSHER PARTS & SERVICES • GYRATORY • CONE • JAW • SIZERS • ROLLS

Learn More

R Crusher Wear Parts Reference Guide

This Guide has been developed to help Dealers personnel to expand their knowledge of Crusher Wear part options & terminology and help relay this information to end users in a clear and

Learn More

C series jaw crushers - Wear parts application guide

The jaw crusher is a compression type crusher. Feed material is crushed between fixed and mov- able jaw dies. Large particles are crushed in a single layer,

Learn More

cone crusher series manual

HP® series cone crushers HP200™, HP300™, HP400™, HP500™, HP700™, HP800™ :::Luckcome. cedar rapids crusher eccentric inner bush dealers usa new product hammer crusher and machine copper parts shipping from china hp800 hydr motor oilgear hydura hydraulic driv used crushers oilgear piston pump. cedar rapids crusher eccentric inner bush dealers usa new product hammer crusher and

Learn More

C Series™ jaw crushers - Corporation

Our industry-leading stroke is amplified from top to bottom, being at its longest in the lower parts of the cavity. This increases the open area between the jaw

Learn More

PDF Jaw Crushers JW Series - TerexPDF

Available as static jaw crushers for a custom fit for your application or available in pre-engineered modular and portable options for easy transport and installation. MODULAR PORTABLE STATIC Modular Model Main Components Motor Size Capacity (MTPH) Shipping Configuration MJ42 JW42 (30" x 42") Jaw Crusher, 40" x 14' Feeder 150 hp (110 kW

Learn More

Jaw crusher parts - Outotec

Thanks to their robust design, you can rely on these jaw crusher spare parts to be the backbone of the most demanding applications. Known for cost efficiency and reduced downtime,

Learn More

PDF C series jaw crushers Wear parts application guidePDF

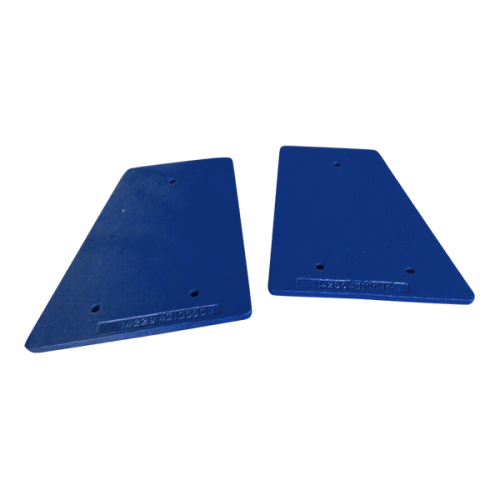

In crushers like C105 and C3055, the jaw die design on the ends is different. The lock-ing wedges on these crushers are located behind the jaw dies rather than at the top of the jaw die. Jaw dies can be allowed to wear until the thickness is 60 to 65 mm thick, or the teeth are worn flat. On other crushers the ends of the jaw dies are much thinner.

Learn More

WEAR IN STONE CRUSHER PLATE - IJARIIE

decreases in jaw crusher and after certain period plate failure occurs which the feasibility of using point load-deformation-failure (PDF) relationships.

Learn More

PDF ® C Series™ jaw partsPDF

The jaw crusher is a compression type crusher. Feed material is crushed between fixed and movable jaw dies. Large particles are crushed in a single layer, referred to as single-layer crushing. Smaller particles are crushed rock on rock, referred to as multi-layer crushing. C Series™ jaw crusher basic concepts Open profile Closed profile

Learn More

Jaw Crusher Parts | Crush Tech

Jaw Crusher Parts. JAW CEDARAPIDS (ALL SIZES) Swing Jaw Die FA Bellied: 03042-051-03: Jaw Stat die : 03042-051-04: Jaw Stat die Reg Curve: 03042-051-45: Jaw, Stat die Reg Curve: 03042-051-47: TogglePlate590 mm: JW42AX1675: Upper Cheek Plate: JW42AY1410: Lower Cheek Plate: JW42AW1411: Fixed Jaw Wedge Bolt:

Learn More

CRUSHER WEAR PARTS

2 - Crusher Wear Parts Reference Guide EvoQuip supplies a complete range of genuine crushing and screening spare parts that are designed specifically for use in EvoQuip equipment. Using

Learn More

The Most Practical Jaw Crusher Repair and Maintenance Manual

Although the main crushing process is complemented by jaw plates, the crucial parts that give a motion to the moveable jaw plate are toggle plate, pitman bearing and flywheel. The pitman drives the moveable jaw dies to push stone material towards stationary jaws, which would create strong pressing forces to both jaw dies.

Learn More