Cone Crusher - an overview | ScienceDirect Topics

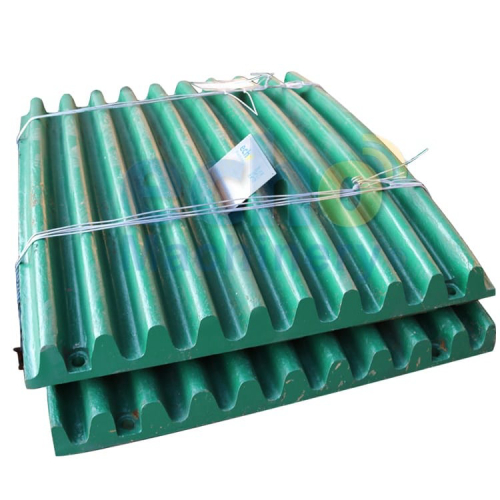

The secondary crushers are designated as Standard cone crushers having stepped liners and tertiary Short Head cone crushers, which have smoother crushing faces and steeper cone

Learn More

Cone Crusher Liners Selection - Wear Parts For Industry - Qiming

2.Crusher Liner’s Material. Cone crusher wear parts, concave and mantle, are casting by manganese steel. Mangalloy, also called manganese steel or Hadfield steel, is a steel alloy

Learn More

How to Find the Right Cone Crusher Liners Manufacturer?

There are three basic types of liners for cone crushers. A standard size has a standard diameter. The "A" dimension is the width of the cone liner. It is a standard measurement for all cone liners. A larger or smaller "A" dimension increases the life of the liner and increases the capacity of the machine.

Learn More

Buy Wholesale cone crusher liner at Affordable Prices - Alibaba

Get back to mining with wholesale cone crusher liner from Alibaba's vast assortment of mining machine parts from hundreds of manufacturers, suppliers,

Learn More

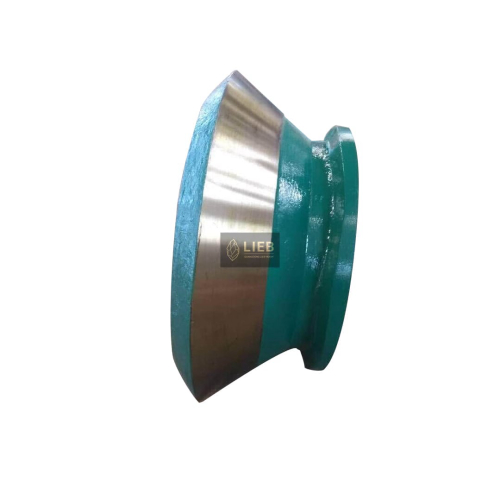

Cone Crusher Wear Parts - Unicast Inc

Durable cone crusher wear parts - bowls and mantles, liners, torch rings, and distributor caps engineered to exceed OEM wear life performance.

Learn More

Cone Crusher Liners | Manufacturing and service of Gyratory

In order to help your site maximise its operational performance, we design Cone Crusher Liners and wear parts that are tailored specifically with your needs and

Learn More

Cone Crusher Wear Parts - Columbia Steel Casting Co., Inc

For better production and longer wear life, choose Columbia cone crusher liners. · Standard, heavy-duty, and custom wear parts for all popular cone crushers.

Learn More

Cone Crusher Liners For Popular Brands With Various

It is the outer sacrificial wear liner that sits inside the upper frame. Common Aliases: Cone crusher liners, Cone crusher wear parts, Manganese cone liners,

Learn More

When to change Cone Crusher liners - Cast Steel Products

Liner thickness Depending on the application, If the Cone Crusher liner is wearing evenly throughout the chamber, when it has worn down to about 1" (2.5 cm) thick at the bottom it is generally time to consider changing it. At about 3/4" to 5/8" (1.9 cm to 1.6 cm) thick, the liner will crack, causing the backing material to begin to disintegrate.

Learn More

Cone Crusher Liners | Manufacturing and service of Gyratory Crushers

Cone Crusher Liners — find the correct solution for your application. Using our knowledge as an Original Equipment Manufacturer (OEM), we ensure that the supplied product is correct for your equipment and application. We offer Cone Crusher Liners tailored to your needs and manufactured to help you find increased productivity.

Learn More

Cone Crusher Liners - Valley Rubber, LLC

Cone Crusher Liners offer considerable reduction in noise and are generally lighter in weight and offer significantly longer life than their steel

Learn More

Cone Liners / Concaves / Mantles for Finlay C - Samscreen

Cones/ Cone Liners / Concaves / Mantles for Finlay C- 1540 Cone Crusher. At Samscreen, we're pleased to provide replacement crushing products for numerous

Learn More

Change Cone Crusher Liners - MGS Casting

When changing linings and also identifying liner wear, follow the instructions in the relevant HP cone crusher instruction manual.

Learn More

HEAVY DUTY CONE LINERS

DUTY CONE LINERS TO IMPROVE WEAR LIFE. PLEASE BE AWARE THAT DUMP CLEARANCE wear throughout the crushing chamber. Benefits Increases crusher uptime.

Learn More

World-Leading Crusher Liners - CMS Cepcor

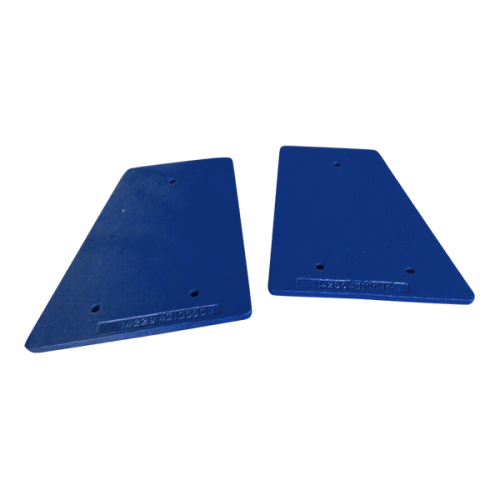

CMS Cepcor® stock a wide range of cavity liner options for cone crushers along with many jaw plate tooth profile options for jaw crushers and various

Learn More

How To Choose Cone Crusher Liners - News - Hysan Road

14/08/ · Cone crusher liner-replacement. When the liner of the cone crusher is not worn to the extent that it needs to be replaced, the tooth plate can be turned around, or the upper and lower parts can be turned around. When the thickness of the liner of the cone crusher reaches 65% to 80%, or the partial wear is deformed and broken, it should be replaced.

Learn More

Cone Crushers - Frog, Switch

Frog Switch not only offers the fine, medium, and coarse liner sets, but also liners that are specifically designed for customers' crushing requirements. Bowl

Learn More

Crusher Liners, Shredder Parts, Mill Liners Foundry- Hunan JY Casting

What We Offer. Hunan JY Casting manufactures crusher wear parts (cone crusher liners, crusher jaw plates, crusher blow bars), shredder wear parts (shredder hammer, grates, caps, anvils), mill liners (lifting plates, shell liners, end liners), and apron feeder pans for the most popular brands.

Learn More

CS Series Cone Crusher Liners - Hunan JY Casting

Experience customer support beyond what you'd get from ® crusher dealers. Hunan JY Casting offers high-quality CS series cone crusher liners for your ® crusher-guaranteed to perform as well as (or better than) OEM crusher parts. Hydroset™-style crushers have been around for decades. As the brand names have changed

Learn More

Cone Crusher Explained - saVRee

Purpose of Crushers. A crusher is a machine designed to reduce the size of large rocks to smaller rocks, gravel, sand, or rock dust; this is essential for efficient transport of the product via conveyors etc. Crushing is the first of many stages that lead to separation of the mineral (s) from the waste (gangue) material.

Learn More

cone crusher liner | spare bush for crusher merlin rp

Cone Crusher Parts. Cone Crushers are the earliest cone crusher in the world with over 50 years. 4829-7591, 3 ft, short head, 3′ SH bowl liner, 824. Cone Crusher Liners | Crushing Wear Parts. CSP is a leading supplier of cast, forged, and fabricated wear solutions to OEM and aftermarket crusher operators.

Learn More