Types Of Stone Crushers Available For Sale - aqua stone

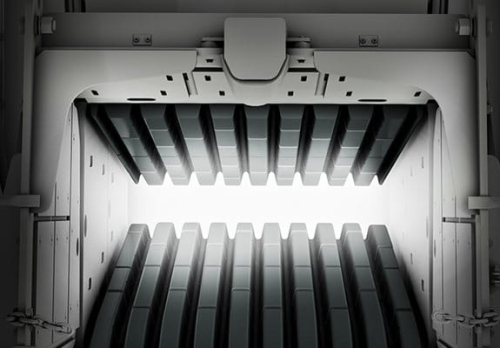

Jaw Crusher For Sale Jaw Crusher. Jaw crushers are the most common types of stone crushers for sale. They work by applying a compressive force on the material until it breaks. It comprises two jaws positioned in a V shape. The jaw located down is stationary and acts as the platform for holding the stone.

Learn More

Crushers - All crusher types for your reduction needs

Different types of crushers are optimal for distinct crushing needs · Jaw crushers. Jaw crushers are mainly used as primary crushers. · Gyratory crushers.

Learn More

What is the best type of stone crusher in the second ... - Quora

The cone crusher is better. Jaw crushers are widely used as primary crusher, and the shape of aggregate is not good. Cone crushers are widely used for secondary

Learn More

Different types of crushing equipments - Constro Facilitator

Different types of crushers. There are three types of crushers. · Jaw Crusher. A Jaw Crusher is one of the main types of primary crushers in a

Learn More

Types Of Stone Crusher From Canada-HN Mining Machinery Manufacturer

Types of Stone Crusher plant . Crushing plants make use of a large range of equipment that makes the full stone crushing plant. It consists of the screener, feeder, loading, unloading, conveyor, hopper, separator, crusher. The main important part of the whole plant is the crusher. Other equipment totally depends on that.

Learn More

Types Of Crusher - Working Principles of Crushers - Fabo

According to the working principle, crushing machines are divided into the following types: cone crusher. jaw crusher. impact crusher. These are the most basic distinctions. There may also be sub-types of these machines. For example, impact crushers have varieties such as vertical shaft crushers or tertiary crushers. Kırıcı Tipi.

Learn More

Crushing technology - kleemann

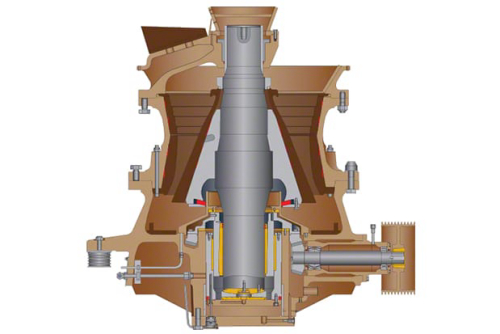

Cone crushers are the choice for use in medium-hard to hard and abrasive natural stone as well as for raw material preparation in mining applications. The cone

Learn More

Crushed stone types - mnih.radschnellweg-ma-hd.de

The Thermal Resistance or R-value depends on the thickness of the material. These values have been calculated for a 1" thick dimension stone sample. The center column in the table above lists values for the thermal conductivity of the natural stone types . The k-value is a measurement of the rate of heat transfer through a solid material.

Learn More

What Are The Four Main Types Of Crushers?

Hammer Crusher. The most common type of crushing machine used is called a hammer mill or an impact mill (a new name for the same device). A hammer mill normally consists of three main parts, a cylindrical body known as the "hammer", which turns on its axis, movable jaws that move along with the cylinder, and headstock that holds the jaws in

Learn More

Crusher - Wikipedia

Type Hardness Reduction ratio Gyratory crushers Soft to very hard 4/1 to 7/1 Cone crushers Medium hard to very hard 3/1 to 5/1 Compound crusher Medium hard to very hard 3/1 to 5/1 Horizontal shaft impactors Soft to medium hard 10/1 to 25/1

Learn More

Stone Crusher Type And Image

stone grinding machine photo-ore crusher-XSM Crusher. Images for stone grinding machine photo File:Stone Grinder.jpg Wikipedia, the free encyclopedia Full resolution (1024 × 681 pixels, file size: 114 KB, MIME type .

Learn More

7 Different Crushed Stone Sizes and Their Applications - ReAgg

1 - The # 1 crushed stone grade is the largest of the crushed stone grades and includes stone between 2-4 inches long. This material is great for larger jobs or for filling in larger holes. #3 - This size of the stone ranges from 1/2 to 2 inches long. This material is a great choice for railroad projects and those that require drainage.

Learn More

Choosing the right crusher - Buying Guides DirectIndustry

Jaw crushers; Cone crushers; Impact crushers, also known as hammer crushers. Why choose a jaw crusher?

Learn More

Types of Stone Crushers and How to Select Crushing Equipments

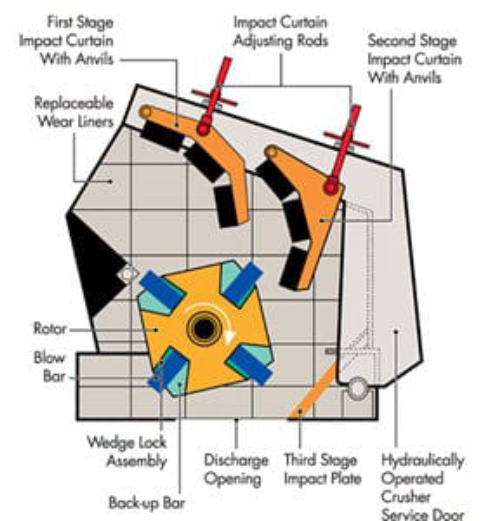

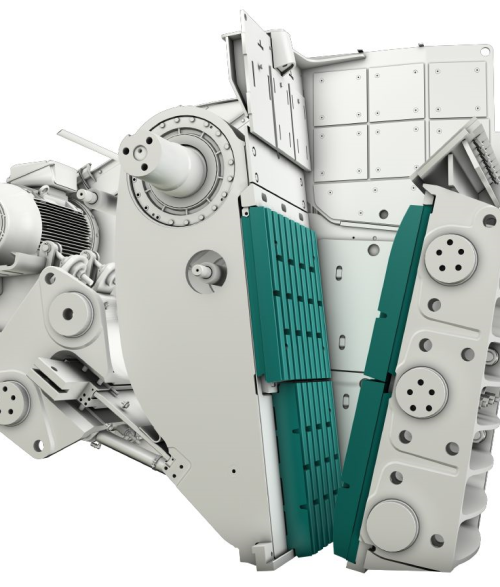

Horizontal shaft impact crusher (HSI) The horizontal shaft impact crusher (HSI) is used in the secondary or tertiary crushing stage, and is usually used for crushing applications where the

Learn More

Types of Stone Crushers and How to Select Crushing

Types of Stone Crushers and How to Select Crushing Equipments · Jaw Crusher · Gyratory crusher · Cone crusher · Horizontal shaft impact crusher (HSI) · Vertical

Learn More

Types of Crushers: What You Need to Know - Machinery Partner

Hammer Mills and Impact crushers: One of the most versatile crushers available, hammer mills and impactors can be primary, secondary, and tertiary crushers. Hammer crushers use continuous hammer blows to shatter and disintegrate material. They are typically horizontal rotating in an enclosed cylinder casing.

Learn More

Understanding the Different Types of Crushers | Agg-Net

More on Aggregate Crushers · Jaw crushers. A jaw crusher is a compression type of crusher. · Cone and gyratory crushers. Cone crushers and gyratory crushers are

Learn More

Stone crusher machine types and their uses

Stone crusher machine types include jaw crusher, impact crusher, gyratory crusher and cone crusher machine. Each stone crusher machine type performs various function in a stone

Learn More

5 Types Of Stone Crushers | Application and Maintenance

There are 5 types of stone crushers: jaw, impact, hammer, cone crusher and VIS crusher, their application and how to maintenance?

Learn More

Crushed stone types - gvn.floranet.pl

By delivering our products to customers directly from the quarry, we are able to operate at a fraction of the cost of typical landscape yards and pass these savings directly to our customers offering you Perth's best prices on all your landscape and garden supplies. Price: AUD $ 60.00 /m³. View Product.

Learn More

What are the types of crushers? - Sandrock Mining

5/27 · The commonly used crushers for sand and gravel aggregate production lines and their advantages, disadvantages, and scope of application are as follows: jaw crusher. 1. Jaw crusher. It has the characteristics of crushing ratio, uniform particle size, simple structure, reliable work, easy maintenance, and economical operating costs.

Learn More