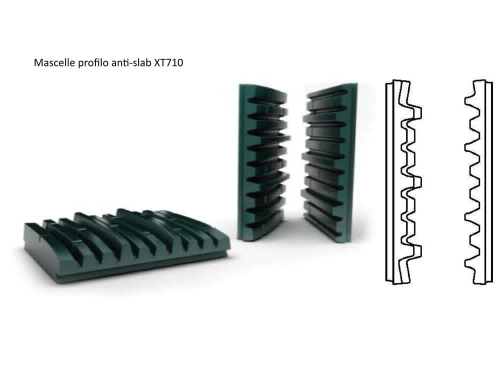

Jaw Crusher - Toggle Plate Seating AREA

Jaw crusher part includes: fixed jaw plate swing jaw plate upper check plate lower check plate toggle plate. Toggle seat &liner. Material: high manganese steel. Jaw Crusher - Heavy Industry. Jaw crusher movement is obtained by using a pivot point located at one end of the The angle between toggle plate and moving jaw decreases when

Learn More

In- depth – Components of a Jaw Crusher - Propel Industries

The bottom of the pitman is supported by a curved piece of metal called the toggle plate. It allows the bottom of the pitman to move up and down

Learn More

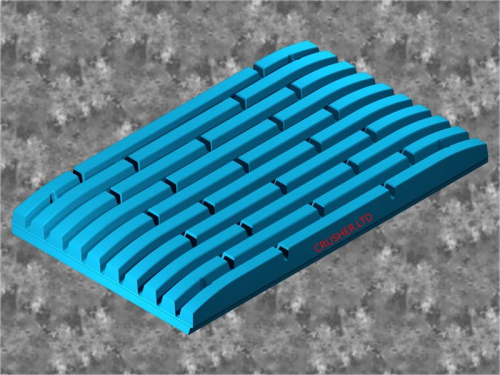

Crusher Toggle Plate - KSnow Materials

MOQ: 2 pieces Size: Customize Hardness: 50/ 60 HRC Elongation: 30 - 50% Delivery time: 7-30 days/ negotiation Manganese Contents: Mn13Cr2, Mn18Cr2, Mn22Cr2,

Learn More

Jaw Crusher Toggle Plate

Toggle plate is an important spare parts of jaw crusher, It is designed to shear protecting crusher components if non-crushable object is introduced to crusher; Jaw plate's high manganese steel castings can be reversed allowing extended life.

Learn More

PDF) Selected design issues of toggle plate selection on the

A jaw crusher is a kind of size reduction machine which is widely used in mineral, aggregates and metallurgy fields. The performance of jaw

Learn More

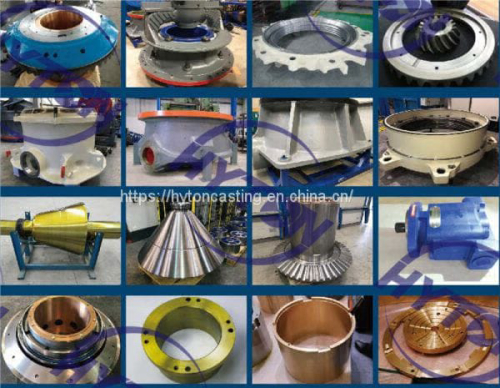

Jaw Crusher Parts - SHANVIM

TIC INSERT JAW PLATE. The use of high-manganese steel or super-high manganese steel jaw plate as base material, in their work place composite inlaid carbide,

Learn More

Jaw Crusher Toggle Plate Manufacturer from Indore

Material: High Manganese Steel. Usage: Jaw Crusher. Toughness: Good.

Learn More

jaw crusher toggle plate material | eti company

At the same time, the material is crushed by multiple forms such as squeezing, rub , and grinding; when the moving jaw moves downward, the angle between the toggle plate and the moving jaw becomes smaller, and the moving jaw plate leaves the fixed jaw Crusher plate under the action of the pull rod and spring. The crushed materials are

Learn More

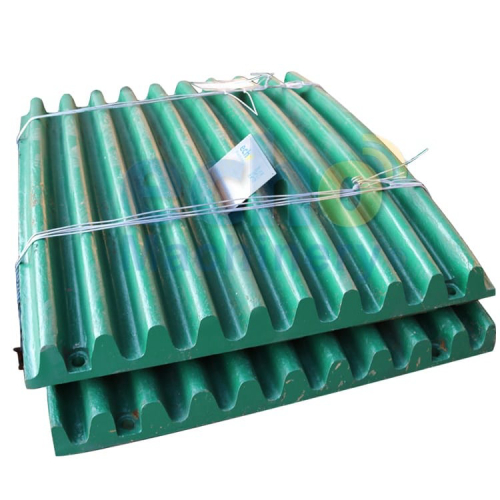

How to Choose the Right Jaw Plates for Jaw Crushers - Ware Resistance

Jaw plates are among the most important jaw crusher parts. They often determine the finished product size and production capacity. Jaw plates are usually made of high manganese steel or medium-carbon-low-alloy cast steel, with different materials providing different advantages, depending on material and crusher types. ·High Manganese Steel

Learn More

MEKA Jaw Crushers - Berkshire Engineering Supplies

High quality material and unique design ensures outstanding durability. The back faces of all jaw plates are machine grounded to provide a firm fit to the body

Learn More

What are the Materials of the Jaw Crusher Plates and Which is Better

High manganese steel High manganese steel is the traditional material of the jaw plate of jaw crusher, which has good impact load resistance. However, due to the structure of the crusher, the opening angle between the movable and fixed jaws is too large, which is easy to cause abrasive sliding and deformation due to deformation.

Learn More

toggle plate for jaw crusher | cfc distributors inc outer upper pivot

Aug 28, · There are different jaw plates material in the market, and some of them suits for hard stone while other is not. Therefore, you have to choose the right jaw plate for your crusher. For example, generally the jaw plate of single toggle jaw crusher is not good at crushing strongly abrasive and hard stone material with large

Learn More

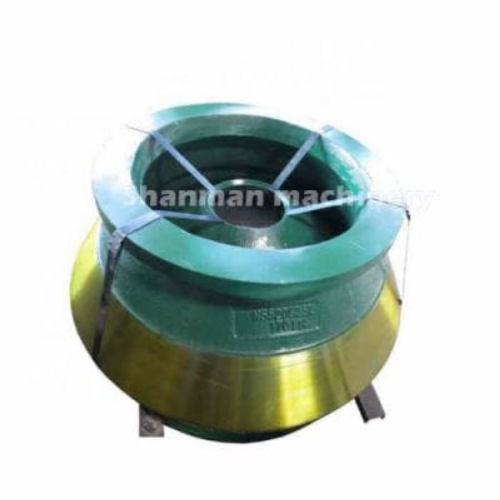

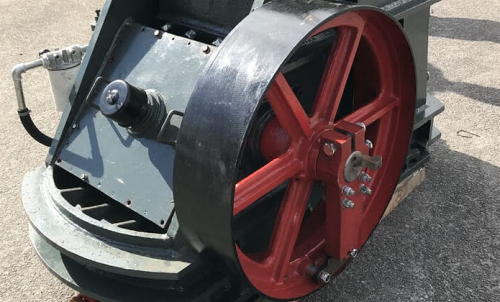

mj series jaw crushers

Single Toggle MEKA Jaw Crusher is designed for applica- tions where cost-efficient primary reduction of hard, abrasive materials is

Learn More

Man Injured by Defective Toggle Plate on Jaw Crusher

The crushing force of the machine is made by an eccentric shaft and is transferred to the crushing zone by a toggle plate system. If uncrushable

Learn More

What are the Materials of the Jaw Crusher Plates and Which is Better? - EB Castworld

The usual composition of medium manganese steel (%): 0.7-1.2C, 6-9Mn, 0.5-0.8Si, 1-2Cr and other trace elements such as V, Ti, Nb, rare earth, etc. The actual service life of medium manganese steel jaws can be increased by more than 20% compared with high manganese steel, and the cost is equivalent to that of high manganese steel.

Learn More

Jaw Plates: How to Choose the Right One for Different

Medium-carbon-low-alloy cast steel is a widely used wear-resistant material at present. Mainly because of its high hardness and suitable

Learn More

Jaw Crusher Toggle Plates vs. Hydraulic Toggle Relief

4/10 · Traditionally, jaw crusher toggle plates are made of metal machined or cast in a way that they are expected to fracture or bend at a certain pressure, indicating something too hard

Learn More

How To Change Toggle Plate In Jaw Crusher Video

4. change quality toggle plate q4: jaw crusher stops work, while movable jaw is in good condition probable reasons: 1. tension spring break 2. tension rod break Toggle Plate – Construction

Learn More

Jaw Plate Materials | Crusher Mills, Cone Crusher, Jaw Crushers

jaw crusher plate suppliers and jaw crusher plate Details: 1.jaw plate material :Mn14Cr2 and Mn18Cr2 2.high manganese jaw plate 3.jaw plate is use to jaw crusher plate.Place of Origin:

Learn More

What is the best material for crusher jaw plates?

12/23 · Mn18Cr2 is the most popular material for casting jaw crusher jaw plates. This Mn18Cr2 jaw plates widely in crushing difficult and non-abrasive blasted rock, medium and non

Learn More

A REVIEW - African Journals Online

nip, jaws, pitman, eccentric shaft, toggle plate, drawback rod, cheek plates, bearing, crusher frame, pulley and flywheel. 2.1 Nature of Feed Material.

Learn More