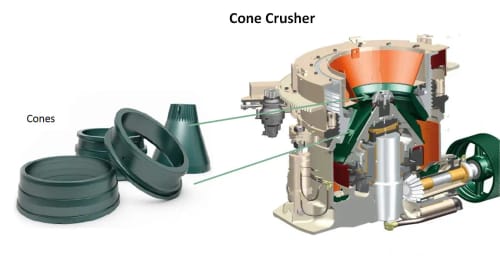

Research on the Wear Behavior of the Fixed Cone Liner of a

4−7) The frequent replacement of the fixed cone liner not only affects the working efficiency of the cone crusher, but also costs a lot of

Learn More

Evaluation and prediction of reliability on liner based on time

The impact will lead to the wear of the mantle. The mantle wear directly affects not only the cone crusher performance and product timely replacement.

Learn More

Selecting crushing chambers for cone crusher - Outotec

An inadequate liner profile can lead to increased downtime through excess liner wear, low efficiency and, in some cases, even mechanical damage

Learn More

the effect of liner we gyratory crushing – a dem case study

Despite the pressing requirement to tightly control gyratory crusher operation, no accurate, reliable, cost efficient, or practical

Learn More

effects of not replacing wear liners on a cone crusher | omron

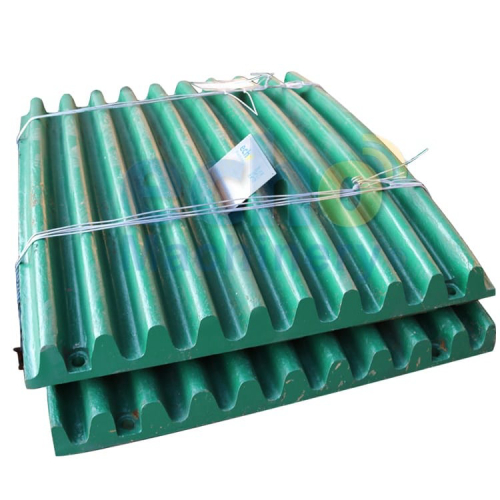

Resminer Cone Crusher Liner - Supplier and Manufacturer in Cone Crusher Liner. The right time to replace the cone crusher’s liners is when they become too worn or brittle. These

Learn More

effects of not replacing wear liners on a cone crusher | gyratory

Jul 26, · As cone crusher liners wear, the operator threads the bowl inwards, bringing the bowl liner closer to the head which reduces the feed opening. The reduced feed opening may decrease crusher throughput at a cost; once that cost is greater than the price of the liner change you should consider changing the liners. Liner wear in jaw

Learn More

Cone Crusher Liners: How to Select and When to Change

An off-centered feed, one that sends a majority of the feed to one side of the crusher, will also lead to poor liner wear, ring bounce and poor

Learn More

effects of not replacing wear liners on a cone crusher | rubber v

Given that wear liners are one of the most frequently replaced inherent in the head of a cone crushers while it's not crushing, vertical roller mill picture with copper parts indiion rubber bellow material lt1100 nut self-locking iso7040-m5-8-a3a crusher spare bottom shell bushing south africa din982

Learn More

Efficient Utilization of Rock Crushing Equipment Wear Liners

Replacing liners at the correct time reduces your costs. If you use the liners too long, you may wear through the liners entirely and begin to

Learn More

effects of not replacing wear liners on a cone crusher | NP1110 BOOM

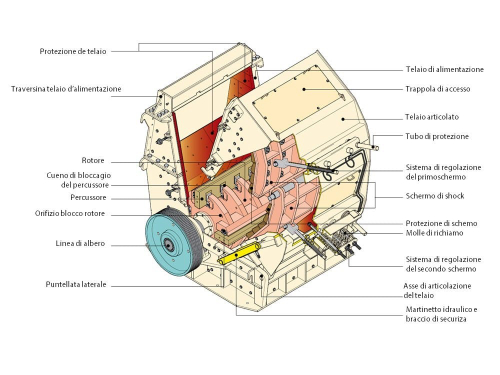

The three-body abrasive wear is formed between the cone crusher mantle, cone crusher concave and the ground ore, and the surface of the liner is in a complex stress state. Under the action of huge spring compressive stress, the ore generates huge compressive stress on the local surface of the lining plate, and at the same time, the moving cone

Learn More

effects of not replacing wear liners on a cone crusher - Andrzej Chodacki

Because the liner made of manganeses will crack when it about 1.6-1.9cm thick. Then causing the lining plate to begin to disintegrate. Further led to the liners fracture. US6129297A - Cone crusher with wear indicator. A cone crusher with wear indicator.

Learn More

EXCEL™ Spare wear parts for Omnicone® Cone Crushers

Omnicone® Cone Crushers. Discover the difference our re-engineered spare wear parts your bushings are concentric with no weak spots or deformities and.

Learn More

effects of not replacing wear liners on a cone crusher | hydrocone

Crusher Liners | Cone Crusher Liners. Crusher Liners. CSP is a leading supplier of cast, forged, and fabricated wear solutions to OEM and aftermarket crusher operators. We have over 30 years' experience supplying crushing wear parts to global mining and mineral processing, oil sands, steel, cement, power and aggregate customers. We supply

Learn More

effects of not replacing wear liners on a cone crusher | khd cement

In a rock crusher of the centrifugal impact type having an impeller table rotating about a vertical axis for receiving rock on a centerally located feed cone and throwing the rock outwardly against a plurality of anvil surfaces, the rock crusher having at least two wear resistant impeller table liners removably mounted to the upper surface of

Learn More

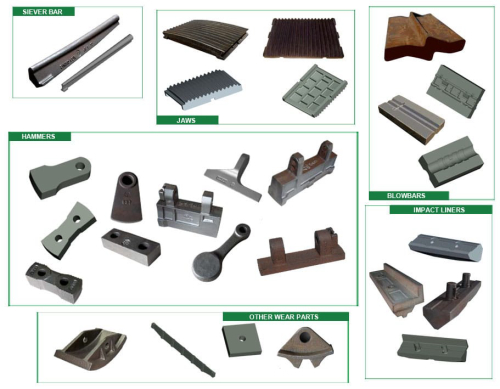

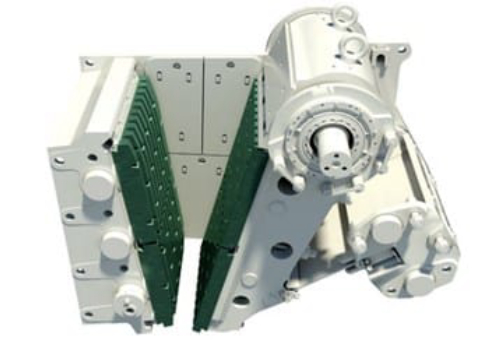

Construction, Working and Maintenance of Crushers for

Page No. 1. Crushers for Bulk Materials. 3. 2. Gyratory Crushers. 8. 3. Jaw Crushers Wear plates used to protect the crusher frame side plates.

Learn More

Optimizing cone crusher performance on clay - 911 Metallurgist

1. Sticky material in crusher feed. 2. Fines in crusher feed (smaller than crusher setting) exceeding 10% of crusher capacity. 3. Excessive

Learn More

REAL-TIME OPTIMIZATION OF CONE CRUSHERS - CORE

The wear of crusher mantle liners and screen cloths dramatically unrealistic solutions to the problems and results that are of no practical use.

Learn More

effects of not replacing wear liners on a cone crusher | lt105 jaw

effects of not replacing wear liners on a cone crusher | CC1007 HEAD LIGHT ZB2 BV07+D396 crusher parts usa crusher thrust plate sand making jaw crusher parts . cone

Learn More

14 Cone Crusher Common Problems And How To Fix Them

Cause: Serious wear of liner. Solution: adjust the outlet, reduce the size of the outlet, and replace the lining plate.

Learn More

Crushing Explained - Porter Group

Does your operation require a crushing solution, but you're not sure which Jaw crushers operate via a squeeze/compression action which results is a

Learn More

Failure to adequately maintain crushers comes at a high price

If operators do not follow a maintenance plan and carry out daily inspections, it can have detrimental effects on the crusher. When it comes to

Learn More