Mineral Processing - DECHEMA

Mineral processing is the first step in the solid mineral extractive process. The goal is to produce granular mate-rial which meets a specific set of requirements in terms of material composition and physical characteristics (espe-cially granulation). The minerals are then used either as » Crushing » Pre-sorting »

Learn More

Efficient modeling and control of crushing processes in

Efficient Modeling and Control of Crushing Processes in Minerals Processing. Marcus Johansson c Marcus Johansson, 2019. Licentiatavhandlingar vid Chalmers

Learn More

Crusher - an overview | ScienceDirect Topics

Crusher. The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. From: Mineral Processing

Learn More

Crushing in Mineral Processing - 911 Metallurgist

In mineral processing or metallurgy, the first stage of comminution is crushing. Depending of the type of rock (geometallurgy) to be crushed

Learn More

Mineral Processing - an overview | ScienceDirect Topics

Mineral Processing. Mineral processing, also known as ore dressing, mineral beneficiation, or mineral engineering, is defined as the science and art of separating valuable metallic and nonmetallic minerals from unusable gangues. From: Mineral Exploration (Second Edition), 2018. Download as PDF. About this page.

Learn More

mineral processing handbook - AusIMM

Mineral Processing Handbook 11/11 - 1st printing Printed in U.S.A. TABLE OF CONTENTS SECTION I PAGE 6–163 All along the processing line, Feeders, Grizzlies, Crushers, Scalpers, Classifiers, Washing Plants, Sizing Screens, Conveyors, Equipment is

Learn More

PDF] Efficient modeling and control of crushing processes in

This thesis focuses on developing models of crushers and equipment used in Efficient modeling and control of crushing processes in minerals processing.

Learn More

PDF) Overview of Mineral Processing Methods

03/08/ · Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent

Learn More

Dust Control in Mineral Processing Operations - CDC

Reducing dust levels in iron ore processing operations Soiling clothes with crushed limestone dust (rockdust) for testing

Learn More

Outotec educates industry on minerals processing

20/08/ · Outotec’s expertise in the area of minerals processing was seen recently as it added a forged head to its range of crushers. The Xtreme head adds extra durability to any crusher in an industry which makes a living off reliable rock crushing equipment. Chad Smallwood, Outotec’s senior vice president for crushing products

Learn More

basics in minerals processing handbook pdf

basics in mineral processing handbook pdf - Basalt Crusher. MOBILE CRUSHER Mobile Crusher Introduction. Mobile crusher also named protable crusher is a new crusher equipment, it provides a new field of business opportunities

Learn More

Analysis and Modelling of Mineral and Element Composition

Comminution in mineral processing plants takes place as a sequence of crushing (coarse comminution) and milling processes (fine comminution). The crushing

Learn More

Crushing Mineral Processing

16/01/ · In mineral processing, the reduction of minerals by crushing and grinding may be regarded as having one or other of two main objectives: the attainment of a size appropriate

Learn More

PDF MINERAL ENGINEERING & FUEL TECHNOLOGY 4 Semester B. Tech Dept. of ...PDF

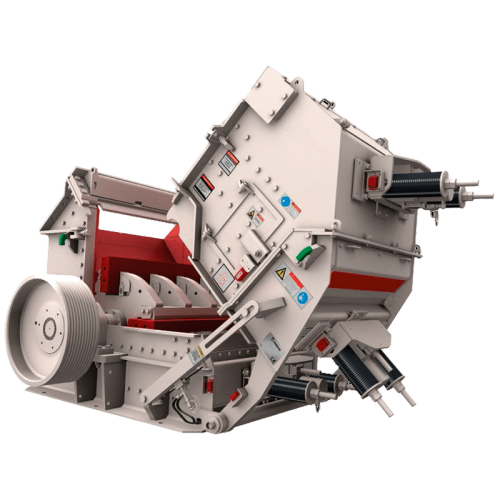

Crushing is the first stage in the comminution process main aim is liberation of the valuables minerals from gangue. 2. Size of the ore from run of mines may be 1.5 m but by crushing the size is reduced to 10-20 cm 3. Dry operation is done in 2 to 3 stage. 4. Secondary crushing produce size of 0.5 to 2cm 5.

Learn More

Understanding Mineral Liberation during Crushing Using

Abstract: Coarse comminution test-work and modeling are powerful tools in the design and optimization of mineral processing plants and

Learn More

AT CRUSHING TECHNOLOGY - Mineral Processing

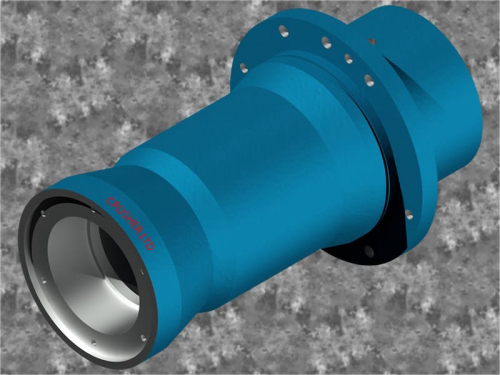

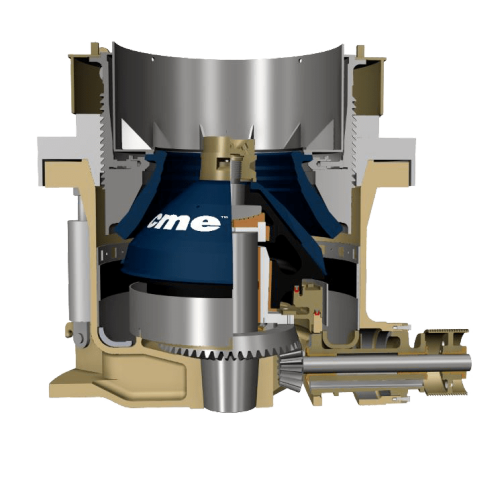

The CRUSHING TECHNOLOGY provides a comprehensive tabular overview of all stationary and mobile crushing plants, which are used in a wide range of applications in the extraction and processing of minerals. For example, this overview includes the technical data of cone crushers, jaw crushers, roll crushers, impact crushers and hammer crushers

Learn More

Unit Operations in Mineral Processing - MyCourses

Comminution in a mineral processing plant involves a sequence of crushing and grinding steps until the appropriate size is achieved.

Learn More

PDF) Mineral Processing: Crusher and Crushing - ResearchGate

08/11/ · Abstract. Mineral Processing: Crusher and Crushing; Types of Crusher; Types of Crushing; Local Quality and High quality ; International and Country/Hand made. Content

Learn More

Basics in Minerals Processing - AusIMM

BASICS IN MINERAL PROCESSING. CONTENT. Introduction. 1. Minerals in operation. 2. Size reduction. 3. Crushing. Grinding. Size control.

Learn More

PDF) Overview of Mineral Processing Methods - ResearchGate

Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue minerals. It is done in order to produce a concentrate containing most of the ore minerals and a

Learn More

Mineral Processing

Comminution – particle size reduction by dry crushing of “run-of- mine” ore followed by grinding of dry or slurried material;. 2. Sizing – the separation of

Learn More