Crusher - an overview | ScienceDirect Topics

13.3.1.1 Primary Crusher. Primary crushers are heavy-duty rugged machines used to crush ROM ore of (−) 1.5 m size. These large-sized ores are reduced at the primary crushing stage

Learn More

Crushers - an overview | ScienceDirect Topics

Primary coal crusher: Used for larger coal size. The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. Secondary coal crusher: Used when the coal coming from the supplier is large enough to be handled by a single crusher. The primary crusher converts the feed size to one that is

Learn More

Different Types Of Crushers Machine Of Primary,secondary And Tertiary

Examples of primary crushers are jaw crusher; Gravel crushing process,Gravel crusher, for sale,equipment Rock is crushed in two or three different phases: primary, secondary and for secondary and tertiary crushing. crushers crush all types of rock but Stone crusher machine for sale used for crushing plant in India

Learn More

Construction, Working and Maintenance of Crushers for

For example, jaw crushers using this method of compression are suitable for For primary crushing with a reduction ratio of 6 to 1.

Learn More

chapter 14. aggregate production - Assakkaf

A primary crusher receives the stone The output of the primary crusher is fed to a secondary crusher, which further Example 1 (cont'd).

Learn More

TLC for Primary Crushers | E & MJ

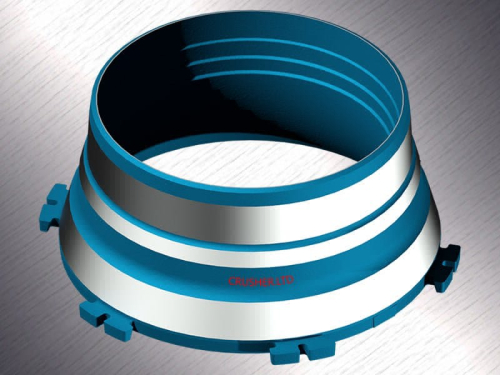

Primary gyratory crushers are easily the hardest working piece of fixed plant on a mine site. The gateway between extraction and processing, they bear the brunt of continuous operation, high feed volumes, and are subject to rock particles of extreme size variation and hardness. It is therefore vital that they are kept in top condition

Learn More

Right Primary Crusher for Aggregate Projects | Oreflow Australia

A primary crusher plays an important role in a mineral processing plant. It reduces the size of large rocks wherein the smaller pieces are

Learn More

Primary Crusher Foundation Drawings Sample

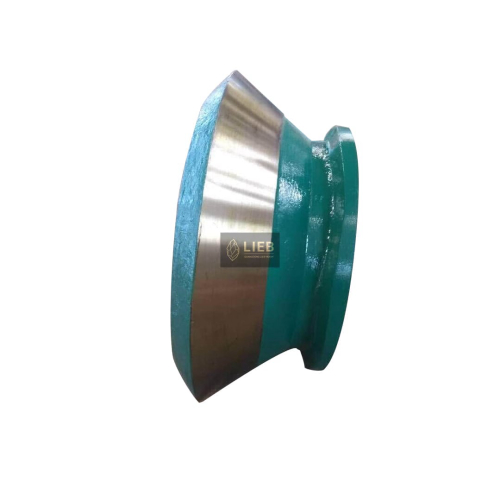

5.1 introduction. gyratory crushers were invented by charles brown in 1877 and developed by gates around 1881 and were referred to as a gates crusher [1]. the smaller form is described as a cone crusher. the larger crushers are normally known as primary

Learn More

Crushers I manufactor | thyssenkrupp Mining Technologies

Primary crushing. In primary crushing larger run-of-mine materials, for example rocks or ore lumps are reduced to smaller fragments. If not

Learn More

Crushers and Their Types - IspatGuru

Crushers are classified into three types based upon the stage of crushing they accomplish. These are (i) primary crusher, (ii) secondary crusher

Learn More

Primary Crusher Example Manufacture and Primary Crusher Example

Primary Crusher Example - manufacturer, factory, supplier from China. Industrial Manganese Steel Jaw Crusher Spare Parts. Well Transported Manganese Steel Jaw Crusher Spare Parts. Stone Crusher Simple Structure Vibrating Feeder. Iron Ore Slag Rod Mill Crusher Machine.

Learn More

Primary Impact Crushers | FABO Machinery

Primary Impact Crusher. Fabo Primary Impact Crushers lower the secondary crushing requirement, provides a high level of reduction ratio and help to increase the plant production capacity to its highest level while processing materials with moderate or low abrasiveness. These machines are produced in two different types according to usage

Learn More

PDF TECHNICAL NOTES 5 CRUSHERS - Mineral TechPDF

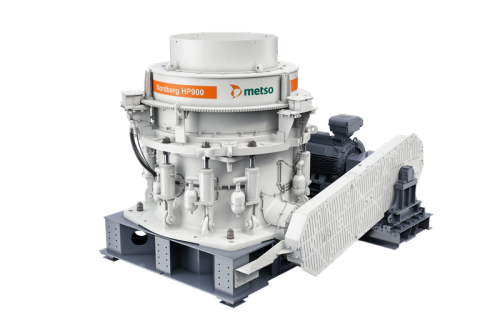

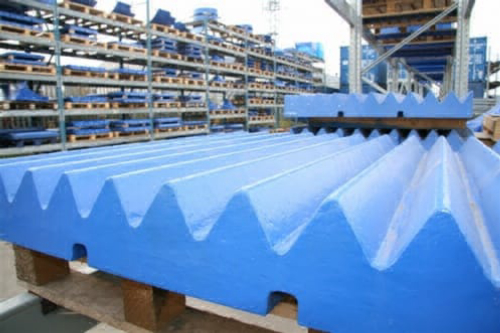

Figure 5.1 Schematic diagram of a crusher showingg the open- and closed-side settings. 5.1 Jaw and Gyratory Crushers. Jaw and gyratory crushers are used mostly for primary crushing. They are characterized by wide gape and narrow discharge and are designed to handle large quantities of material. The capacity of the crusher is determined by its size.

Learn More

Crusher - Wikipedia

Blake crusher-the swing jaw is fixed at the lower position · Dodge crusher-the swing jaw is fixed at the upper position · Universal crusher-the

Learn More

primary crusher plant

TAKRAF's range of primary crushing plants Primary crushing plants can be equipped with gyratory crushers, jaw crushers, twin-shaft sizers, double-roll crushers,

Learn More

What Type of Crusher Is Best for Primary Crushing?

Hammermills can be used as a primary crusher in many types of aggregate and industrial applications, including limestone, marble, shale, gypsum,

Learn More

PDF ROCK CRUSHING PLANT APPLICATIONS ADVICE - Oklahoma Department of ...PDF

For example, the calculation for PM would be: - 650 hp * 0.0007 lb/hp-hr = 0.455 lb/hr - 0.455 lb/hr * 1500 hours per year / 2000 lb per ton = 0.34 TPY B. Rock Processing Operations Point ID lb/hr Description Process Rate TPH Factor lb/ton Control Efficiency PM Emissions TPY

Learn More

Selecting the right type of crushing equipment - Quarry

In most aggregate crushing plants, primary crushing is carried out in a jaw crusher, although a gyratory primary crusher may be used. If

Learn More

AMIT 135: Lesson 5 Crushing - Mining Mill Operator Training

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding

Learn More

Primary Crusher - an overview | ScienceDirect Topics

Primary coal crusher: Used for larger coal size. The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring

Learn More

Choosing the right crusher - Buying Guides DirectIndustry

A crusher is a machine that uses mechanical energy to break blocks of stone, concrete, or other building materials into smaller blocks of a specific grain size. They are particularly used in the mining industry to reduce the size of ore blocks and facilitate their processing. Crushers are designed to receive blocks of a maximum size.

Learn More