Jaw Crusher - an overview | ScienceDirect Topics

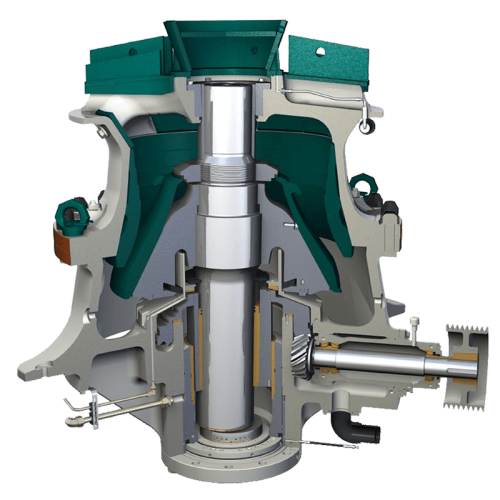

The gyratory crusher can, just like a jaw crusher, accept boulder sizes close to 1.5 m (for the largest equipment). – This crusher can handle products with a Mohs hardness that is not necessarily less than 5. – As is the case for jaw crushers, there is not any mutual sliding on grinding surfaces, but simply rolling of the nut on concaves.

Learn More

Choosing the Right Rock Crushing Equipment - Amcast

A gyratory crusher consists of a concave surface and a conical head constructed from heavy steel casting. It works by using a mantle that

Learn More

PDF 2. Gyratory CrushersPDF

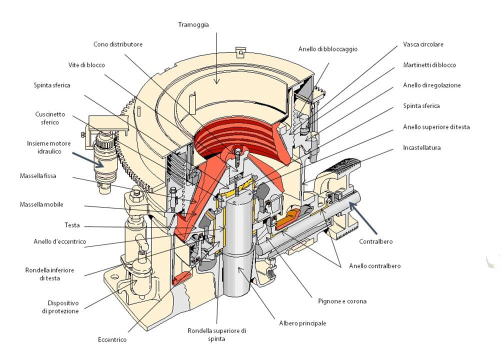

jaw and gyratory crushers. Manufacturers redesigned their gyratories to reduce the feed opening, decrease the closed-side setting, and in- The gyratory crusher has been built in three types known respec- tively as the suspended-spindle, the supported-spindle and the fixed- spindle type. The second type, with the hydraulic piston as the sup

Learn More

Jaw Crusher Manufacturer | CITIC HIC

Crushers · Gyratory Crusher · Jaw Crusher · Semi-mobile Gyratory Crushing Station · Single-cylinder Cone Crusher · Multi-cylinder Cone Crusher.

Learn More

Jaw Crusher VS Gyratory Crusher - Luoyang Dahua

Comparison of performance advantages of gyratory crusher and jaw crusher. The outstanding advantage of the gyratory crusher is that the crushing wall is large, which can reach -9.5, and sometimes it can be as high as 13.5. The production efficiency is high, and the work is relatively stable. Either side can feed ore and can be crowded with ore.

Learn More

Gyratory Crushers | Crusher Mills, Cone Crusher, Jaw Crushers

gyratory crusher ( jrtr krshr ) ( mechanical engineering ) A primary breaking machine in the form of two cones, an outer fixed cone and a solid inner erect, Gyratory Crusher Parts,Gyratory Crusher Offers Manufacturers,

Learn More

Gyratory Crusher HOW IT WORK | Crusher Mills, Cone Crusher, Jaw Crushers

Gyratory crusher,primary gyratory crushers maintenance,working if you have used Gyratory Crusher of questions,gyratory crusher sizing how gyratory crusher works - Crusher South Africa how a gyratory crusher works | Crusher Solutions Gyratory and cone crushers work in pretty much the same way, although they have slightly

Learn More

AMIT 135: Lesson 5 Crushing - Mining Mill Operator Training

Gyratory Crushers; Jaw Crushers; Impact Crushers. Typical rules for primary crusher selection: Rule 1: Always use a jaw crusher if you can

Learn More

jaw crusher and gyratory crusher | hydraulic bottom shell bushing

To determine the capacity of jaw and gyratory crushers, Broman divided the crusher chamber into different sections and determined the volume of each section in terms of the angle that the moving jaw subtended with the vertical. Broman suggested that the capacity per stroke crushed in each section would be a function of the top

Learn More

between gyratory crusher and a cone crusher

Gyratory Crusher Cone Crusher Mantle Differences Jul 25 Difference between jaw crusher and gyratory crusher Any of you that are at all familiar with the

Learn More

Gyratory Crusher (GY model)| Crushing/Grinding

Gyratory Crusher (GY model)' Design is a combination of the most modern engineering techniques. ・Our newest 60-109 GY provided to Kansai Airport Project

Learn More

Crusher - Wikipedia

Jaw crushers: Soft to very hard: No limit: Dry to slightly wet, not sticky: 3/1 to 5/1: Heavy mining, quarried materials, sand & gravel, recycling Gyratory crushers: Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening. Gyratory crushers can be used for primary or secondary

Learn More

Heavy Duty Jaw Crushers|Stone Crusher Manufacturer in India - Puzzolana

JAW CRUSHER. PUZZOLANA offers complete range of single toggle jaw crushers for all types of rock, ores & minerals. These crushers are designed to operate in most rugged environment and need less maintenance. Available in 14 sizes 30" x 20" to 72" x 60" - upto 1000 TPH. Puzzolana's range of single toggle jaw crushers are designed with an upward

Learn More

Jaw crusher - SlideShare

Gyratory Crusher • A gyratory crusher is similar in basic concept to a jaw crusher, consisting of a concave surface and a conical head; both

Learn More

Compare Gyratory Crusher vs Jaw Crusher - Mineral Processing & Metallurgy

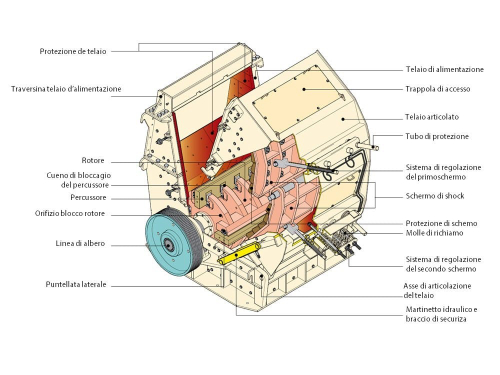

Jaw and gyratory crushers are heavy equipment and are not used extensively in the food industry. In a jaw crusher, the material is fed in between two heavy jaws, one fixed and the other reciprocating, so as to work the material down into a narrower and narrower space, crushing it as it goes.

Learn More

image of gyratory crusher

Image Of A Jaw Crusher And A Gyratory Crusher [click pics to enlarge]. 4' standard cone crushing plant - all electric plant, 4' std. cone crusher w/125-hp motor, gator 5' x 16' 2-deck cedarapids jp3054 .primary gyratory crusher reduction ratio,jaw, impactor, or gyratory crushers are usually used for initial reduction. series gyratory crusher: due to high reduction ratio.

Learn More

Jaw Crusher - Stone Crushers & Grinding Mills for Mines and Quarry

As the first process of stone crushing line, Jaw Crusher always plays important role. This machine is possess of optimized crushing chamber, heavy eccentric shaft and high manganese steel jaw plate, which takes advantages of high efficiency, strong crushing ability and low investment costs. Applications: Mining, metallurgy, construction

Learn More

Going underground: Jaws or a primary gyratory?

Above 1,000 tph, primary gyratory crushers begin to look interesting, and after the throughput reaches 2,000 tph, jaw crushers are very rare, with the

Learn More

Gyratory Crusher Explained - saVRee

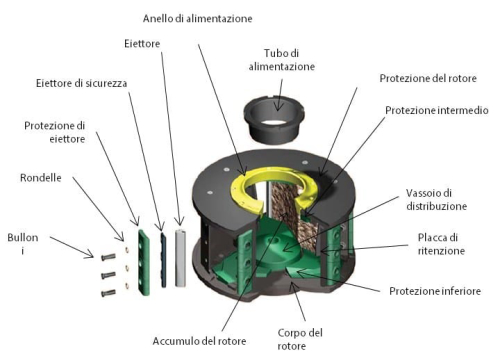

Gyratory Crusher Components Gyratory crushers were invented by Charles Brown in 1877 and further developed by Gates in 1881 (they were commonly referred to as

Learn More

Crushers - Gyratory and Jaw - Holdtrade (UK) Ltd. Website

Gyratory crushers are primary crushers that receive blasted material from the mine or quarry. Similar to jaw crushers they work by grinding the material between

Learn More

Jaw Crushers for Mining in Canada - Nelson Machinery Equipment

Jaw Crushers for Mining in Canada - Nelson Machinery Equipment Category: Crushers Home / Shop / Crushers 1 2 3 4 8 9 10 → Showing 1-16 of 158 results ID: N0762 2″ X 6″ STURTEVANT LAB JAW CRUSHER Sold ID: C1365 2.5″ X 4″ BICO LAB JAW CRUSHER ID: C1151 2.75″ X 5.5″ ATLAS LAB JAW CRUSHER ID: N00002 2.75″ X 5.5″ ATLAS LAB JAW CRUSHER ID: C1528

Learn More