Gyratory Crusher - an overview | ScienceDirect Topics

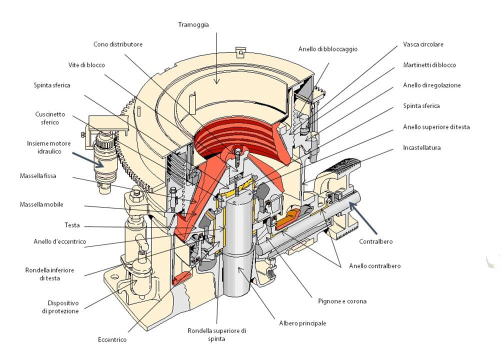

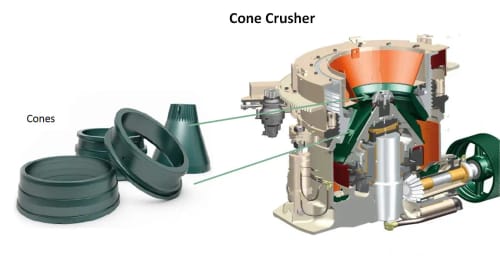

A gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sides.

Learn More

CG800i GYRATORY CRUSHER SERIES

CG800i crushers are built to be robust, reliable and efficient. Primary Gyratory Crusher. Model No. / Size Please Refer to Installation.pdf.

Learn More

Gyratory Crushers - Mineral Processing & Metallurgy

17/02/ · Gyratory Crushers. The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a typical section is shown in Fig. 5. It consists essentially of

Learn More

Gyratory Crushers

Gyratory and Jaw Gyratory Crusher. Resource Technologies No. Type Type Client Country Feed Material Year [cm] 239 KB 54"x67" KB 137-170 Great Khingan Jinxin Mining Co., LTD Chalukou Mine China Molybdenum ore 238 KB 63"x75" KB 160-190 Baogang Group Baiyunebo Iron Mine China Overburden 237 KB 54"x75" KB 137-190 Huatuo Mining

Learn More

Gyratory Crusher Pdf - Buy Gyratory Crusher Pdf Product on

The HGT Gyratory Crusher adopts the automated control system. It is equipped with various types of sensors to monitor the lubrication pressure and temperature, the bearing temperature, the rotation speed and the axis' position, a PLC as well as a touch screen. By these, every production stage can be monitored, displayed and controlled in real time.

Learn More

PDF Instruction Manual for Gyratory Crusher PXZ-1500IIPDF

The gyratory crusher of CITIC Heavy Machinery company is mainly used in mines, quarries, metallurgy and other fields. During its process of design and manufacturing, we take full account of the influence the equipment has on human health and safety. Although some accidents can

Learn More

Gyratory Crusher Pro | manufactor | thyssenkrupp Mining Technologies

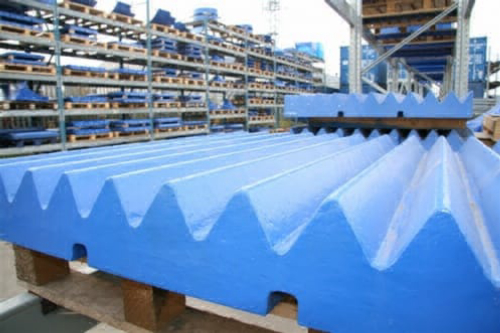

The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only. It is normally serrated and, together with the upper part of the mantle, it forms the initial crushing zone. The coarsely crushed material is then reduced to the desired product size in the crushing chamber below.

Learn More

Gyratory Multi-Size 17X0500-02.0706-English.pdf - Technical

Section 0 — Safety SUPERIOR MK- II Gyratory Crushers 0-5 17X0500-02.0706 Some General Safety Instructions 1. Do not remove, cover or disable any installed safety devices, guards, warning signs or tags. They are attached to equipment to warn personnel of possible danger and prevent injury. Use OEM replacements in the event any safety devices, warning signs or tags become damaged or unreadable.

Learn More

IS 4255 (1967): Gyratory and Cone Crushers

IS 4255 (1967): Gyratory and Cone Crushers [MED 17: on the type of spindle support, a gyratory crusher can be of the suspended.

Learn More

PDF Gyratory crusher working principle pdf - southtours.comPDF

Gyratory crusher working principle pdf The working principle of the crushers on the left is an exhibition of the "Standard Shrine with straight concaves" is a section through any vertical plane, radial in the crushing chamber of one of the intermediate dimensions of the crusher. to understand the overwhelming action in such a room it is useful to consider the process as if each step took

Learn More

Crushing and screening solutions - Agg-Net

Our crushers and screens are highly engineered and precisely tested to ensure that they run and deliver 24 hours . a day, 365 days a year. 's experience and competence in crushing and screening technology ensures that we provide equipment that is the best in the world. The use of premium-quality components ensures that your equipment runs at high performance,

Learn More

PDF) A Gyratory Crusher Model and Impact Parameters

The objective of this research was to develop a mathematical model for gyratory crushers to help in the prediction of energy consumption and

Learn More

PDF Industrial Solutions Gyratory crushers - ThyssenKruppPDF

The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only. It is normally serrated and, to- gether with the upper part of the mantle, it forms the initial crushing zone. The coarsely crushed material is then reduced to the desired product size in the crush - ing chamber below.

Learn More

TECHNICAL NOTES 5 CRUSHERS - Mineral Tech

Gyratory crushers can produce size reduction ratios over a somewhat larger range of 3:1 to 10:1. The primary operating variable available on a crusher is the set and on jaw and gyratory the open-side set (OSS) is specified. This reflects the fact that considerable portions of the processed material fall through the crusher at OSS and this determines the characteristics size of the

Learn More

QH441-OperationManual - Crusher Works

39 Item Part No. Image 1 DE1007 2 DE6000 3 DE6004 4 DE6015 5 DE6006 DE5024 6 DE6007 7 DE0027 tagout)

Learn More

PDF Crushing and Screening Handbook - AusIMMPDF

the crusher and scalp out fi nes. Primary gyratory crushers - ideally suited to all high-capacity primary hard rock crushing applications. Jaw crushers - we have more installed jaw crushers than anyone in the world. The lead-ing choice due to their high reduction ratio and heavy duty design. Cone crushers - capacities available to suit all

Learn More

1 Crushing - Springer

crusher. Gyratory Crushers. Gyratory crushers are the second class of primary crushers and were developed more recently than the jaw crushers. They are much

Learn More

A Case Study on Main Shaft of a Gyrator Crusher - Zenodo

results confirm the efficiency of proposed corrective method. Keywords—Fatigue failure, finite element method, gyratory crusher, condition monitoring.

Learn More

PDF Top service TSUV Gyratory Crushers Safer, smarter and more ... - FLSmidthPDF

Designed to crush even the hardest ore 1. The bar-type spider'sfour-bolt design reduces the amount of time required for removal. Further, its rectangular design reduces the overall amount of space necessary during maintenance. 2. Spiral bevel gearingallows for larger installed power on the crushers. 3.

Learn More

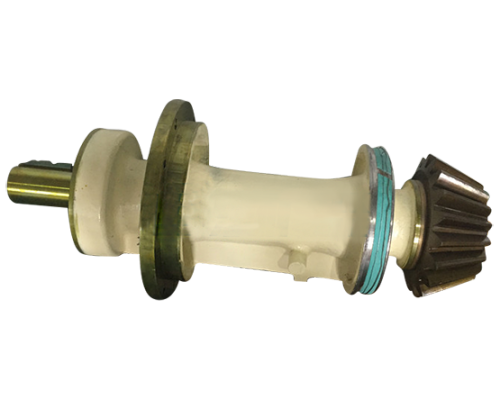

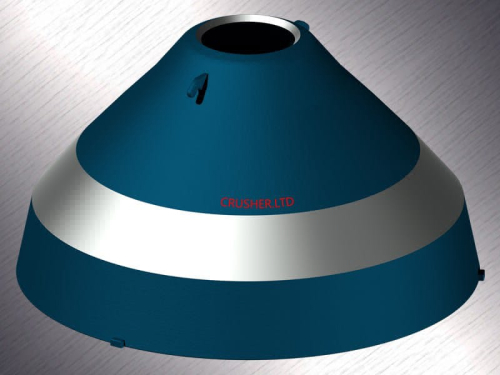

PDF Excel Premium ComponentsPDF

1.309.347.6155 • Toll Free 800.523.9129 [email protected] ExcelFoundry.com Excel Premium Components Gyratory Style Crushers Mainshaft Sleeve Mainshaft Head Nut Mantle

Learn More

Mining crushers SuperiorTM MKIII Primary Gyratory

create a Primary Gyratory crusher with the best performance, highest capacity, and highest reliability. 4. 6 7 Introducing the industry leading SmartStation is an expert in automating

Learn More