How does a Single Toggle Jaw Crusher work? | RUBBLE MASTER

Clean the breather filters and install new oil filters and seals. Remove the dirt and debris from the crusher surfaces at the end of the day Keep Up with Your Daily Maintenance Check the jaw ties and cheek plates for wear and check tightness of bolts every day Check your closed side setting for maintaining a consistent end product.

Learn More

Jaw Crusher Working Principle - How Does It Work

A jaw crusher crushes large blocks of stone and abrasive materials. The stones go through a primary and secondary crushing process. Jaw crushers have two jaws: one remains fixed while the other one moves. The jaw crusher working principle works on the reciprocating movement of the movable jaw. This part crushes and compresses ores and Continue reading Jaw Crusher Working Principle - How

Learn More

Jaw Crusher - Jaw Crusher Mannufacturers | AGICO Cement

The jaw crusher is divided into three types according to the width of the feeding port: large type, medium type, and small type. The models with inlet width greater than 600 mm are large types, between 300 and 600 mm are medium-sized types, less than 300 mm are small types. AGICO is one of the jaw crusher manufacturers in China.

Learn More

How Does a Jaw Crusher Work - Kemper Equipment

All jaw crushers reduce large sized rocks, ore, or other material by a compression action. A fixed jaw, mounted in a V-shaped alignment, is the stationary

Learn More

what is jaw crusher working principle

what is jaw crusher working principle What Is the Use and Working Principle of Jaw Crusher? Impact Crusher Working Principle what is working principle of jaw crusher Grinding Mill

Learn More

Jaw Crusher Working Principle Of Jaw Crusher

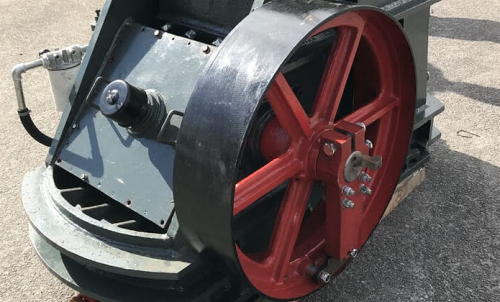

The work method of jaw crusher animation working principle of jaw crusher The motor drives the mobile jaw up and down through eccentric shaft. The angle

Learn More

jaw crusher working video line | Primary Hard Stone Crushing Machine

Working Principle of Jaw Crusher: PE/PEX jaw crusher adopts the electric motor as the power. The eccentric shaft is revolved by an electric motor through v-belts, which causes the swing jaw moving in the preconcerted path to crush the feeding material.

Learn More

Jaw Crusher Working Principle - Conmix Crusher

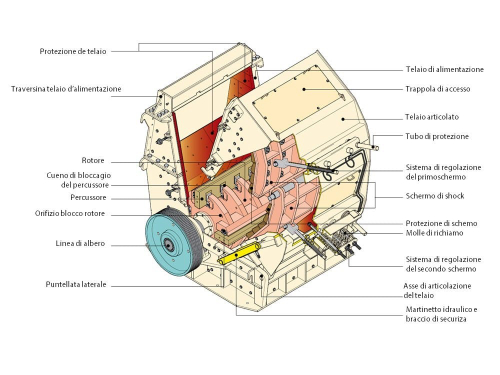

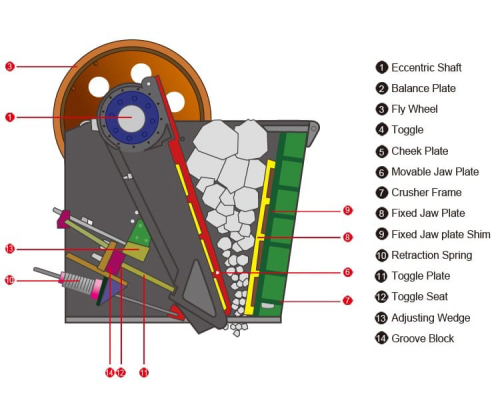

Crushing is done between the two crushing jaws. The moving jaw of the single toggle jaw crusher moves elliptically. A pendulum motion is being carried out by the double toggle jaw crusher. The crushing force is produced by an eccentric shaft. Then it is transferred to the crushing zone via a toggle plate system and supported by the back wall of

Learn More

Jaw Crusher Working Principle - Mineral Processing

Some jaw crushers are on-floor, some aboveground, and others underground. This in many countries, and crushing many kinds of ore. The Traylor Bulldog Jaw crusher has enjoyed worldwide esteem as a hard-working, profit-producing, full-proof, and trouble-free breaker since the day of its introduction, nearly twenty year See more

Learn More

jaw crusher working

together with the "client-oriented" enterprise philosophy, a arduous good quality control technique, sophisticated producing equipment and a sturdy r&d staff, we generally offer superior quality merchandise, superb solutions and aggressive rates for jaw crusher working, portable jaw crusher , vertical vibrator motor , bucket elevator ne plate ,

Learn More

How does lab jaw crusher working? - News - Qingdao Decent Group

Nov 24, · The jaw crusher is a kind of rock crusher. The motor drives the belt and pulley, and the movable jaw moves up and down through the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, thereby pushing the movable jaw plate to be fixed. The jaw plate approaches, and at the same time

Learn More

Jaw Crushers In Action! Crushing Rocks, Concrete, Granite, Bricks

Our jaw crushers have crushed a lot of different stuff over the years and we wanted to make a video of some of the best shots. We have several different sizes of jaw crushers we sell and they do a

Learn More

How A Jaw Crusher Work | Crusher Mills, Cone Crusher, Jaw Crushers

Jaw Crusher has the features of high crushing and even product size ratio.This page is mainly about How Jaw Crusher to Work. How jaw crusher works,primary jaw crusher working principle Jaw crusher operating concept is: The motor drives belt and belt wheel, the eccentric shaft triggers the movable jaw to maneuver down and up, ahead and backward

Learn More

Jaw crusher working principle and characteristics

Feb 17, · Jaw crusher works When the jaw crusher is working, the movable jaws make periodic reciprocating motions to the fixed jaws, sometimes approaching and sometimes leaving. When approaching, the material is crushed, split, and impacted between the jaws; when it is removed, the broken material is discharged from the discharge opening by gravity.

Learn More

Jaw Crusher Working Principle - 911 Metallurgist

A single-toggle pivots at the base of the swing plate which is causing the jaw's arc-like motion. The rock pinching resulting from its flowing/

Learn More

Jaw Crusher Working Principle - m.gravelmill.com

Jaw Crusher Working Principle. Jaw crusher is widely used in industrial and mining enterprises , this is because the aircraft structure is relatively simple , and has a large range of models . Jaw crusher is mainly used as the primary crusher. It can be used with mineral processing equipment , gravel ancillary equipment, it also can be used alone.

Learn More

C96 TOGGLE PLATE C96 single toggle jaw crusher working principle

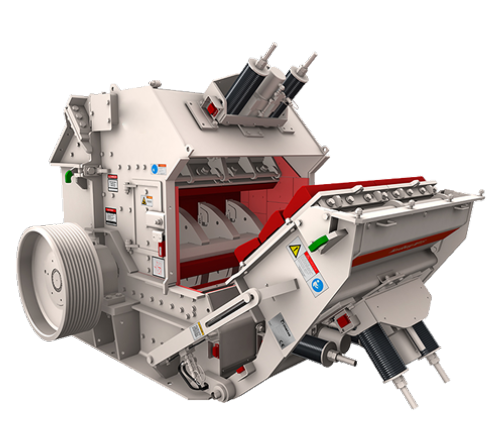

C96 TOGGLE PLATE C96 single toggle jaw crusher working principle tractor mounted crusher jaw crusher eccentric shaft design Quality, Versatility, Reliability for Thousands Less Impact Crushers lippmann 2021-03-22T16:59:40-05:00

Learn More

How Does a Jaw Crusher Work | Jaw Crusher | Kemper Equipment

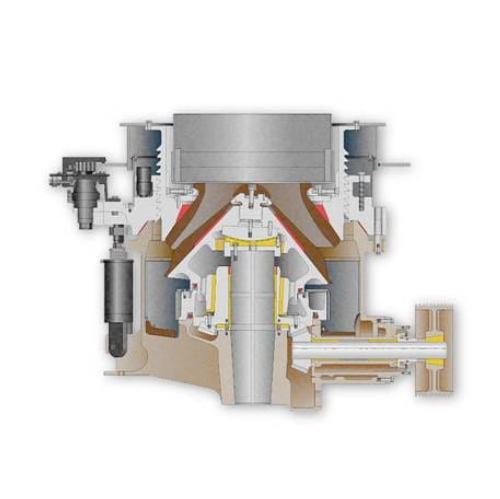

All jaw crushers reduce large sized rocks, ore, or other material by a compression action. A fixed jaw, mounted in a V-shaped alignment, is the stationary breaking surface, while a movable, "swing" jaw exerts force on the feed material by pushing it against the stationary plate.

Learn More

jaw crusher toggle plate | crusher copper bush for sale

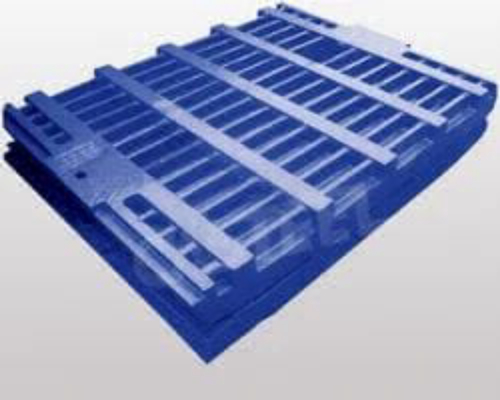

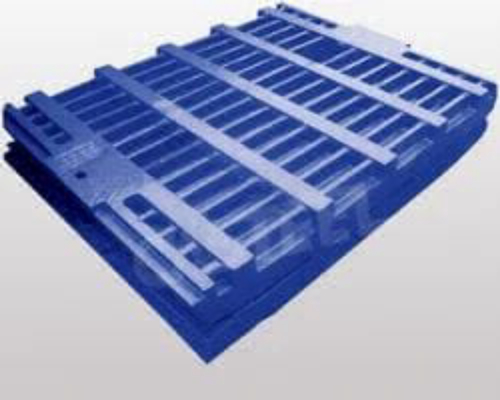

Jaw Crusher Wear Parts - Columbia Steel Casting Co., Inc. The right jaw design can make a big difference for your jaw crusher. Our customers have proven that the right jaw plate design can make a dramatic difference, depending on the application. We have many case histories in which wear life increases of 50% are common, and some in which wear

Learn More

Single Toggle Jaw Crusher With Unique Benefits

As everyone knows, jaw crusher is the most popular rock crusher in use for coarse-size and medium-size crushing (Now we publish a portable rock crusher which is

Learn More

Jaw Crusher Working Principle Manufacturers, Exporters Delhi

The working principle of jaw crushers There is two component of the jaw crusher, Moving side and fixed size. Staff put the material from the top of the machine and ensures that the material is in between the two jaws. Moving side comes and goes however fixed size remains the same. Moving jaw comes and crushes the material.

Learn More