How does a Rock Crusher Work - Jaw Crusher - 911Metallurgist

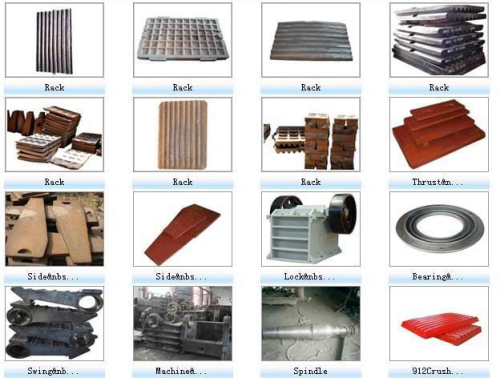

The entire design facilitates lubrication and replacement of shaft bearings. Jaw plates are constructed of manganese steel and have corrugated crushing surfaces which reduce the power required for fracturing material. The jaw plates are built into two pieces to jaw. Those on the swing jaw are interchangeable.

Learn More

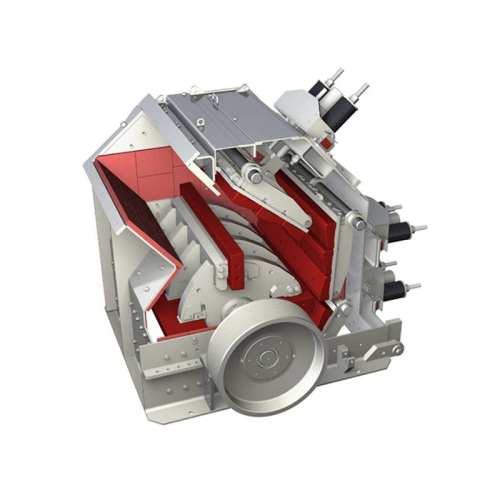

Double Toggle Jaw Crusher Design

The DT (Double Toggle) Model Jaw Crusher is unique in that it has its hinge The advantage of this design is that when the movable jaw Jaw crushers,Jaw breaker, Primary,Mobile,Stone jaw crusher Double Toggle jaw crushers may feature hydraulic toggle adjusting mechanisms. Our design and production are of high position both at home and abroad.

Learn More

What is a Jaw Crusher? – MEKA Crushing Equipment

Feed size, which is around 150 to 300 mm, of the rock or ore from the primary crushing process is reduced to between 50 and 80 mm. Tertiary Crushing. This is the third stage of crushing. The working principle of jaw crushers is based on the reciprocating movement of the movable jaw that compresses and crushes the rock or ore between itself

Learn More

How Does a Jaw Crusher Work | Jaw Crusher | Kemper Equipment

More compact than double toggle designs, the single toggle movement jaw crusher was at one time unable to accept such large feed sizes, though it can typically run faster. the bottom of the “V”-aligned jaw plates is the output gap that dictates the size of the crushed product from the jaw crusher. The rock remains in the jaws until it

Learn More

Development-Design-for-Jaw-Crusher-Used-in-Cement

crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust.Crushers may be used to reduce the size, or change the form, of

Learn More

Jaw Crusher - Eastman Rock Crusher

Jaw crushers are designed to process abrasive hard rock, with aggressively-shaped nip angle, it featurs the crushing ability that can consistently reduce high hardness materials the in the quarrying, mining, recycling, and building materials industries, increases uptime. Hydraulic protection system

Learn More

Design and Analysis of Swing Jaw Plates of Jaw Crusher

The pitman moving on an eccentric shaft on bearing, swing lever (Moving Jaw) swing on center pin. The Rock held in between two Jaws and crushed by mechanical

Learn More

Choosing A Jaw Crusher | Tricon Mining Equipment

Jaw crushers are sometimes also referred to as “rock breakers,” which speaks These design tweaks over time have perfected a machine that's simple enough

Learn More

ROC Jaw Crusher

Thanks to their simple design and rugged construction, ROC jaw crushers are effective and economical for crushing large size bastard rock in quantity.

Learn More

PDF Design and Construction of Rock Crushing Machine from Locally Sourced ...PDF

The shaft of a typical jaw crusher machine is made of hardened steel (high carbon steel). It puts the moveable jaw stock in motion (through the motor, pulley and belt arrangement) that produces the needed force to crush materials. Components of jaw crusher

Learn More

Homemade Jaw Crusher

07/01/ · Would love to be able to make my own crushed stone and gravel. I have screened piles of rock while excavating my house site. I am trying to build a jaw cru

Learn More

how a jaw crusher works and what it is used for

A fixed jaw, mounted in a "V" alignment is the stationary breaking surface, while the movable jaw exerts force on the rock by forcing it against the stationary

Learn More

Small scale mechanized stone crusher, Mechanical design.pdf

Due to their simple design and easy maintainability jaw crushers are widely used Rock is a natural occurring resource found in and on the earth surface.

Learn More

Jaw Crusher Working Principle - Mineral Processing

06/05/ · A jaw crusher size is obtained by looking at its feed opening (gape) and length. As an example, a monster 7959 of 79″ x 59″ (2m x 1.5m) will have its fixed jaws 79″ apart where

Learn More

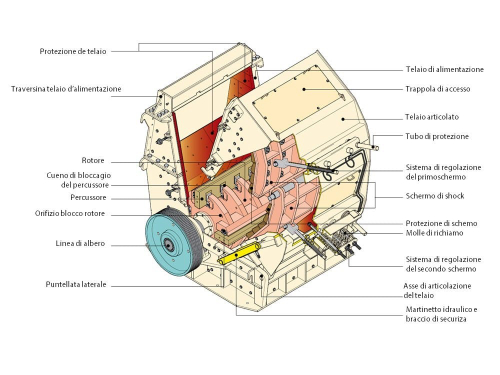

PDF Design of impact stone crusher machine - CitefactorPDF

Jaw crushers These are the oldest type of and the most commonly used crushers in use and have changed little from the original design. In Jaw Crusher the feed is compressed between a stationary and a movable surface. A few of common types of Jaw crushers, in use, are described below • Double toggle jaw crusher • Single toggle jaw crusher

Learn More

SMAN jaw crusher - Shakti Mining

a jaw crushers is a crushing machine designed considering a primary stage crushability for materials such as rock, mineral, rom and building rubble. jaw crushers design focuses on compression type crushing with feed of material being received from the top of the crushing chamber that consists one side fix and other movable type cast manganese jaw

Learn More

Miniature Rock Crusher: Design and Machining

It's a long one! I had previously gone over the function and basic assembly of the rock crusher, however in this video I go into a lot more detail and show

Learn More

Jaw Crusher - JXSC Machine

Jaw Crusher. 【Capacity】 1-130tph. 【Feeding Size】 <1200mm. 【Output Size】 10-300mm. 【Crushing Materials】Granite, dolomite, river pebbles, quartz, calcite, and other materials. 【Application】 Jaw crushers are mainly used at the primary stage to reduce hard and brittle materials size for the next crushing stages, widely applied

Learn More

Jaw Crushers - MEKA Crushing & Screening Plants

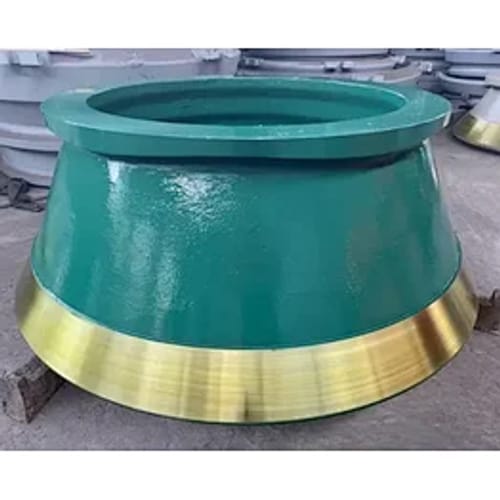

JAW CRUSHER. Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaw; one is fixed while the other makes an eccentric movement. There are also primary and secondary types of these crushers. Jaw crushers are one of the most commonly preferred crushers due to their ability to

Learn More

Jaw Crusher Liner Plate Design & Profile Shapes

22/07/ · These non-choking jaw plates have been developed in two styles, reversible and non-reversible. The advantage of the reversible design has been outlined in connection with its

Learn More

PDF "Computer Aided Design of Jaw crusher"PDF

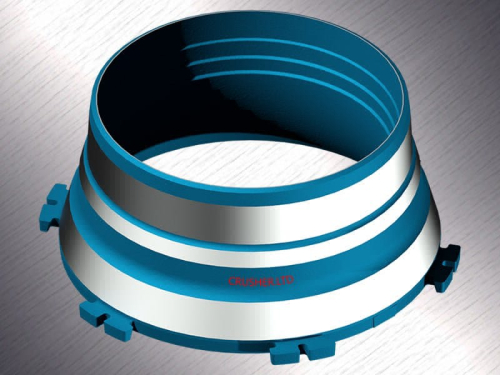

The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws .For instance, a 22 x 30 jaw crusher has an opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" square. Generally primary jaw crushers have the square opening design, and secondary jaw crushers have rectangular opening design.

Learn More