Hp Choke Fed Cone Crushers-HN Mining Machinery Manufacturer

In order to maintain the maximum levels of capacity, gradation, and cubical product, a Cone Crusher must be choke-fed at all times. The best way to keep a choke-feed to the Cone Crusher is with a surge bin (or hopper) and feeder that are located prior to the crusher. Choke-feeding is almost impossible to achieve without a hopper and feeder.

Learn More

Cone Crusher Maintenance - Rock Products Magazine

Keeping the cone crusher choke fed during operation maximizes the effectiveness of rock-on-rock crushing, maintains maximum manganese wear life,

Learn More

Crusher Feed Arrangements | Crusher Mills, Cone Crusher, Jaw Crushers

Large cone crusher can be directly fed with the choke feed arrangement is set by simply choosing the correct stroke for the GP cone crusher - the Jaw crusher unit operation,fines screen and optional fines

Learn More

Cone Crushers And Choke Feeding - Crusher Mills, Cone Crusher, Jaw Crushers

KPI-JCI adds automation to jaw, cone crushers continuous choke feeding. The 1150 mm x 800 mm feed opening provides a maximum feed size of 640 mm. Cone crusher production good practice:secondary and tertiary Choke feeding is important for cone crushers as it maintains a good particle shape by facilitating an inter-particle crushing action;

Learn More

Crusher - an overview | ScienceDirect Topics

Cone crushers were originally designed and developed by around 1920 and therefore These crushers are always operated in choke feed conditions.

Learn More

Crushing and Screening Handbook - AusIMM

Correct choke point. This means the right selection of cavities for feed in question. 8. Crusher itself. New generation cones will.

Learn More

Mobile Cone Crusher Range - PowerX Equipment

Cone feed box level control to maintain choke feeding; Hydraulic crusher setting; Cone overload protection; Heavy duty chassis and track frame; Metal detector

Learn More

Principle of a cone or gyratory crusher. - ResearchGate

basic operating principle of a cone crusher is shown in Figure 4. increase in crushing rate and fractal dimension of the ore due to the choke feeding.

Learn More

Cone crusher basics in 4 minutes — SRP

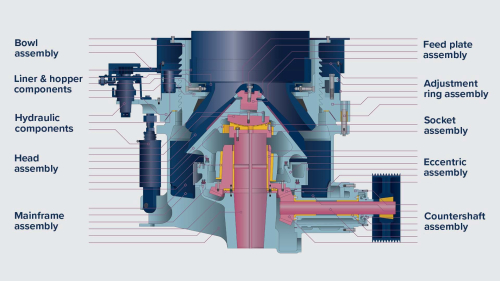

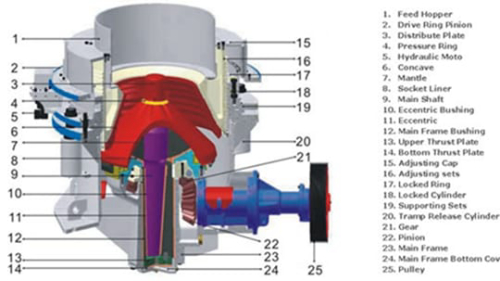

Cone crusher basics in 4 minutes This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing.

Learn More

12 tips to maximize cone crusher productivity

The benefit of staying choke fed is that there will still be rock-on-rock crushing and grinding taking place in the crushing cavity. This helps

Learn More

Cone Crusher - an overview | ScienceDirect Topics

Cone crushers were originally designed and developed by around 1920 and therefore These crushers are always operated under choke feed conditions.

Learn More

PDF HP series cone crushers Wear parts application guidePDF

The crusher should be choke fed so that the crushing chamber is full all the time. This is important, especially in fine crushing. Choke feeding maximizes the amount of multi-layer crushing, improves the shape of the crushing cavity as it wears and improves the crushing efficiency. => Choke feed level for an HP cone crusher is 300 mm or more

Learn More

Understanding the Different Types of Crushers | Agg-Net

Jaw crushers are routinely choke fed to maximize production capacity and ensure that particles are uniformly broken. This promotes stone-on-stone crushing,

Learn More

Hillsboro, OR - Crushers For Sale - Equipment Trader

The three main types of crushers are the cone crusher, the jaw crusher, and the impact crusher. Make sure you understand all of the differences between these kinds before choosing one for your project. Regardless of which type of machine you choose, you should be prepared for some very powerful crushing power. Make sure that anyone who is set

Learn More

What is a Cone Crusher?

12/20 · A choke feed is when the crusher cavity is kept full, without spilling out over the top of the crusher. A minimal feed is when the crusher cavity is kept fairly low, just enough to ensure the crusher continues to work. An anti-spin device can help with minimal or intermittent feeds.

Learn More

crusher choke feeding vs regulated feed

should a jaw crusher be choke fed Stone Crusher Machine. Choke Fed Cone Crusher Henan Ftmmac Mining Machinery Choke Fed Cone Crusher.choke feed jaw crusher Description : Choke Fee

Learn More

The Importance of Choke Feeding a Cone Crusher | Pilot Crushtec

How to choke feed a cone? The material in the crushing chamber should be just over the top of the spider frame. The crushing chamber should be kept full by regulating the feed rate into the crusher. Adjust the level sensor to maintain the height of the material in the chamber; the sensor will start and stop the feeder accordingly.

Learn More

Cone Crusher Choke Feed - Manufacturers, Factory, Suppliers

Cone Crusher Choke Feed We support our buyers with ideal high quality products and high level service. Becoming the specialist manufacturer in this sector, we have gained rich practical

Learn More

Crusher Aggregate Equipment For Sale in HILLSBORO, OREGON - 28 Listings

Browse a wide selection of new and used Crusher Aggregate Equipment for sale near you at MachineryTrader.com. Find Crusher Aggregate Equipment from CEDARAPIDS, KPI-JCI, and , and more, for sale in HILLSBORO, OREGON

Learn More

Maximising productivity from secondary cone crushers

When possible, the secondary crusher should be operated with a flooded crushing chamber, commonly referred to as 'choke feeding the crusher'

Learn More

Maximising productivity from secondary cone crushers - The Weir

5/23 · A Trio ® TP top performing secondary cone crusher from Weir Minerals delivers a fine feed for high throughputs through the tertiary crushers. Operated to its full capabilities, a secondary cone crusher will make your entire plant more productive and efficient. We will be launching the Trio® TP900 at MINExpo in Las Vegas on 26 - 28 September.

Learn More