rebuild mantle gyratory crusher cone crusher for sale australia

Mar 15, · This study aims to analyze the impact of key structural parameters such as the bottom angle of the mantle, the length of the parallel zone, and the eccentric angle on the productivity and product quality of the cone crusher and optimize the

Learn More

rebuild mantle gyratory crusher | GP330 part

Jaw gyratory crushers can handle much bigger chunks of material than comparable gyratory crushers of the same mantle diameter. Jaw gyratory crushers feature a higher

Learn More

Gyratory crusher mantle-bowl structure - Google Patents

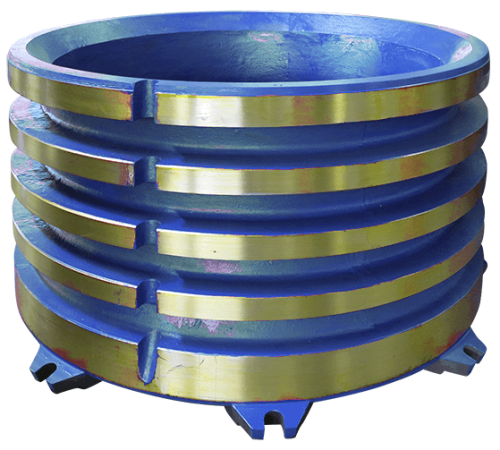

Particularly formed telescopically mating conical elements (mantle and bowl) are disclosed for use in a cone type gyratory crusher as employed for reducing

Learn More

primary mantle repair - Demitec Limited

Demitec has been inspecting, overhauling and repairing gyratory crushers in vaious indutries for more than 25 years. We provide a single source for safe,

Learn More

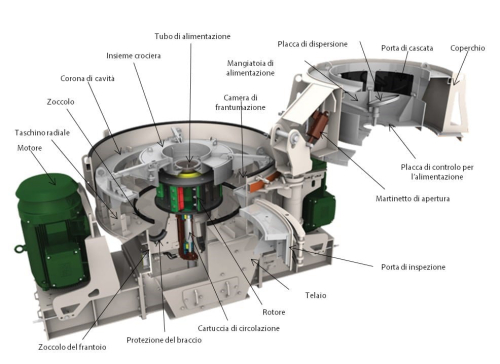

Gyratory crushers - Industrial Solutions CIS

The design of our gyratory crushers and jaw gyratory crushers is based on over the crusher shell and the eccentrically gyrating mantle continu-.

Learn More

14 Cone Crusher Common Problems And How To Fix Them

Solution: Stop the machine, check and repair. 3.Oil pressure is low after oil pump is started. Cause: The oil temperature is low; the pipe is blocked

Learn More

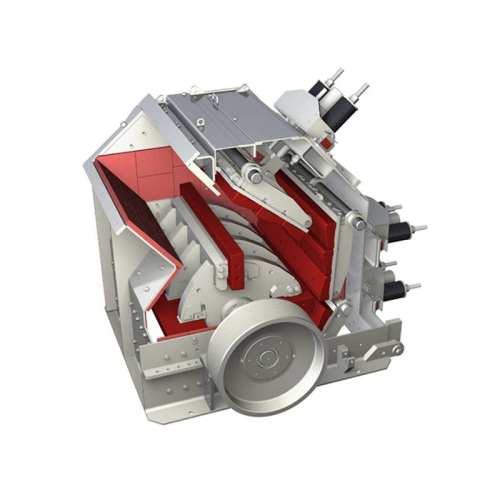

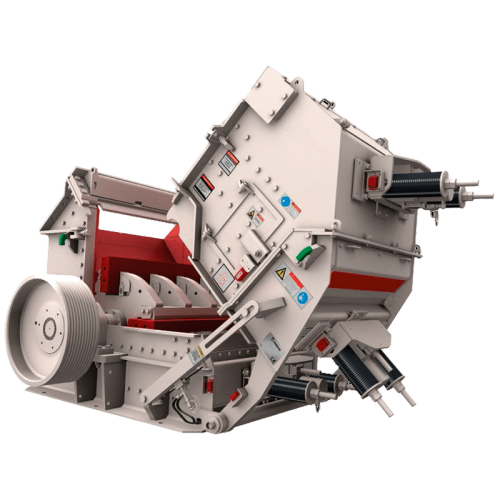

rebuild mantle gyratory crusher hp400 motor crusher sapre countershaft

rebuild mantle gyratory crusher. Crushers recycling or road building our jaw, cone & impact crushers are ready for any job. I4C Impact Crusher. 1050mm (41.3") diameter x 1125mm (44.3") wide Impactor; 375Hp (280kW) engine; Crawler Tracks; Integrated hydraulic folding stockpiling conveyors.

Learn More

rebuild mantle gyratory crusher the department of crusher

IMPROVING GYRATORY CRUSHER PERFORMANCE - H-E Parts Mar 28, · improving gyratory crusher performance Download White Paper March 28, In an Indonesian

Learn More

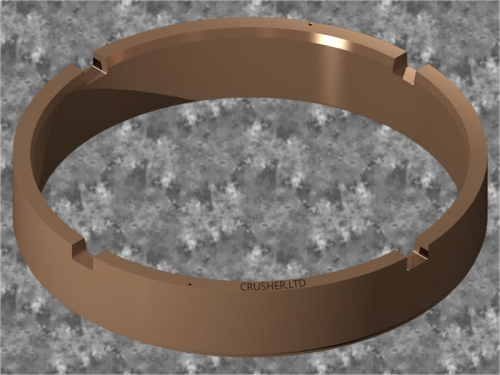

Gyratory Crusher Liners

Increase your operation's efficiency with our expert knowledge and high-quality equipment. We are the OEM manufacturer of Gyratory Crusher Liners.

Learn More

rebuild mantle gyratory crusher | mill spare bearing bush with

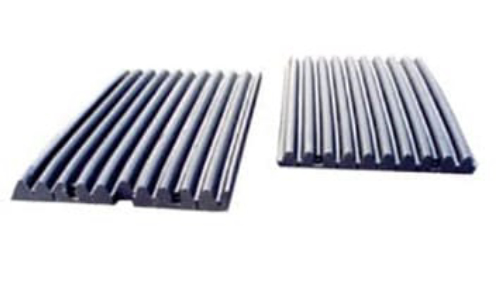

Gyratory crushers are frequently used in the primary crushing stage and a little less often in in the secondary stage. Gyratory crushers have an oscillating shaft. The material is reduced in a crushing cavity, between an external fixed element (bowl liner) and an internal moving element (mantle) mounted on the oscillating

Learn More

rebuild mantle gyratory crusher SG4265 WRENCH, HIT BOX

Name Provider Purpose Expiry Type _ok Olark Identifies the visitor across devices and visits, in order to optimize the chat-box function on the website. Session HTTP CookieConsent Cookiebot Stores the user's cookie consent state for the current domain 1 year

Learn More

rebuild mantle gyratory crusher mining crusher parts online crusher

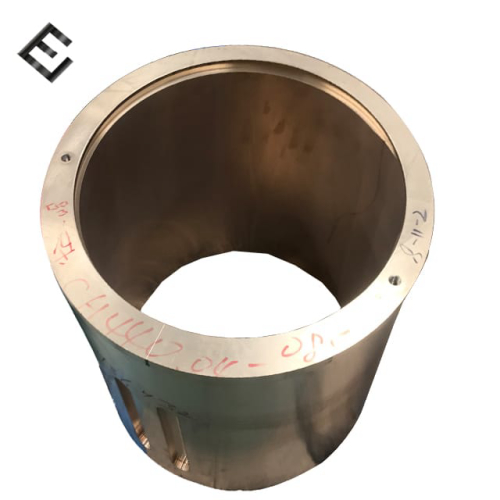

We also offer a full line up of wear materials for your specific needs. Large Cone Crusher bore rebuild. Gyratory Crushers - Mineral Processing & Metallurgy. Feb 17, · Gyratory Crushers. The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a typical section is shown in Fig. 5. It consists

Learn More

how to change a mantel on gyratory crusher

Improves servicing of the cone crusher head This means less downtime the decision as far as replace or rebuild is not always easy Rebuilding these

Learn More

Construction, Working and Maintenance of Crushers for

The crusher is the workhorse of the hard rock crushing industry. A gyratory crusher uses a mantle that gyrates (rotates) within a cone shaped inner surface.

Learn More

rebuild mantle gyratory crusher | portable crusher spare wearing plate

crushing capacity, may find the crusher wear mantle supplied in their gyratory is the wrong profile for processing slippery black schist. This could generate a crushing condition causing material to jump up the cavity, resulting in significantly lower crushing capacity than originally expected.

Learn More

Primary gyratory crusher parts - Outotec

A crusher mantle or a set of concave segments with a longer wear life do not need to be replaced as often. You will need fewer per year but also have fewer

Learn More

rebuild mantle gyratory crusher | track spike shoes

rebuild mantle gyratory crusher Spare parts and wear parts. Gyratory Crushers - Mineral Processing & Metallurgy. Feb 17, · Gyratory Crushers. The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a typical section is shown in Fig. 5. It consists essentially of a gyrating crushing head (521

Learn More

rebuild mantle gyratory crusher shale double roll crusher eccentric bushing

Name Provider Purpose Expiry Type; _ok: Olark: Identifies the visitor across devices and visits, in order to optimize the chat-box function on the website.

Learn More

rebuild mantle gyratory crusher hp500 elbow swivel-90deg

Gyratory Crusher & Cone Crusher Mantle Differences In the Gyratory all the movement is in the bottom of the crusher mantle. This is due to the angle that the main shaft is on. The greater angle of the cone crusher puts the pivot point below the distributor plate.

Learn More

Between a rock and a crusher mantle - Australian Mining

Welding reclamation and hardfacing of gyratory crushers proves its the life of new crusher mantles and to rebuild worn crusher mantles.

Learn More

rebuild mantle gyratory crusher | 1761-cbl-pm05

As oversize rock enters the top of the gyratory crusher, it becomes wedged and squeezed between the mantle and hopper. US6604699B1 - Method for securing a gyratory crusher The

Learn More