Grinding Mill Liners and Wear Parts

Columbia Steel offers a full line of wear parts for rod mills, ball mills, and semi-autogenous grinding (SAG) mills for cement plants. Made in USA.

Learn More

Grinding Mill Liners- An Overview

Grinding Mill Liners- An Overview · Solid liners · These are single units with integral lifters and fewer pieces but the downside is a higher

Learn More

grinding mill liners

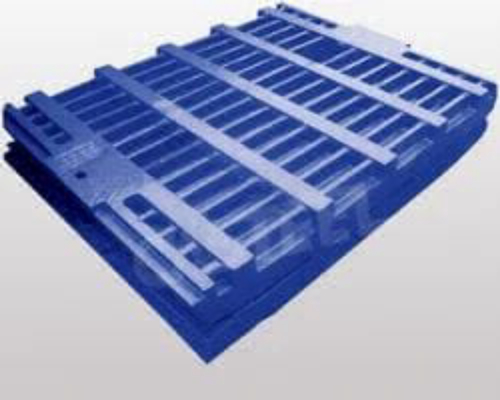

GRINDING MILL LINERS · DIFFERENT TYPES OF LINER PLATES · Coarse Grinding: Rib Liner, Wave Liner, Wedge-bar Liner, Ship-lap Liner, Lorain Liner, Straub Liner etc.

Learn More

Better Surface Quality With Dia3.8m Steel Cement Mill Liners DF067 For

Mill Liners for sale, Quality Better Surface Quality With Dia3.8m Steel Cement Mill Liners DF067 For Grinding Cement on sale of Zhengzhou Qianyue Mill Liners Co., Ltd. from China.

Learn More

Tips to improve grinding profitability with mill liners

A mill lining should be optimized by design in order to minimize problems, utilize the mill's capacity and keep a good liner profile

Learn More

New steel High-Chrome White Iron grinding mill liners

New "Steel" high-chrome white iron grinding mill liners. - For rod and ball mills. - Shell and head liners available. - Custom manufacture in North America.

Learn More

Grinding Mill Liners | Products & Suppliers | Engineering360

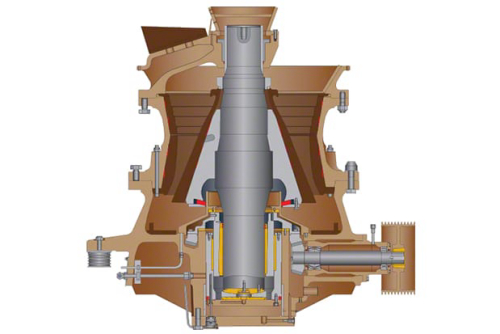

Liners protect the inside of trunnions from the abrasive action of the material slurry. Worn liners can lead to erosion of the trunnions, mill head, and “fit” area. Unless the erosion is stopped, Form: Loose Liner / Pre-fabricated. Industry & Application:

Learn More

Mining - Polycorp

Proudly manufactured in Canada, Polycorp has supplied mill liner solutions for more than 400 grinding mills worldwide. AG/SAG Mill Liners.

Learn More

Selection and design of mill liners - ResearchGate

Liners protect the mill shell from wear and transfer energy to the grinding charge. A careful balance is required to optimise these conflicting

Learn More

Ni-Hard Mill Liners For Cement Industry From Qiming Machinery

For mill liners, our foundry uses ASTM A532 Type 4 to cast. Ni-Hard Mill Liners Material Chemical Composition. The role of different chemical elements in Ni-hard mill liners: Cleaning and grinding: after heat treatment of mill liners, the water and riser root shall be cleaned and polished. During grinding, local overheating shall not be

Learn More

Grinding Mill Liners - EB Castworld % Ball Mill Liner % Grinding Mill

Grinding Mill Liners. Application: Grinding Mill Liners. Hardness: ≥HRC58. Impact value: ≥5J. Material Group: High Cr White Iron: BTMCr15Mo, BTMCr20Mo, BTMCr26Mo. Service Life: 1st Chamber: about 2 years; 2nd Chamber: about 4 years. Process: quenching & tempering treatment to achieve higher hardness and ideal impact value.

Learn More

Grinding Mill Liner Market Report | Global Forecast From 2022 To 2030

The Global Grinding Mill Liner Market Size is projected to grow at a CAGR of 5.5% from to 2030. In , the metal mill liner segment accounted for the largest share of the global grinding mill liner market. The Asia Pacific is expected to be the fastest-growing region during the forecast period. The growth of this market can be attributed

Learn More

Mill liners - The Weir Group

Our mill lining systems offer exceptional life and reliability in the most difficult grinding applications. Mill liners. Optimising grinding mill performance.

Learn More

Cutting-edge Mill Liners

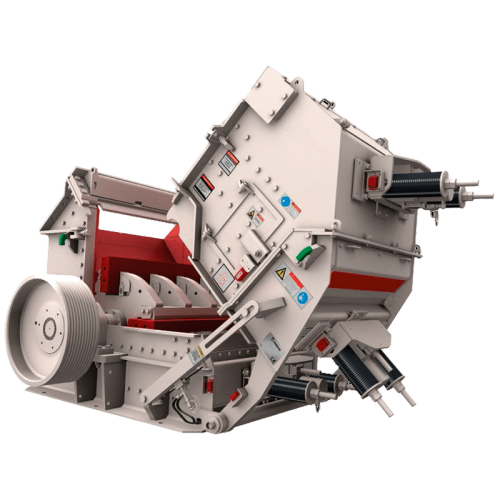

Mill liners fill a basic role: to protect your mills from the intense wear and tear that comes from grinding down hard, raw materials.

Learn More

Shell Liners | Crusher and Mill Liners | CITIC HIC

CITIC HIC has a wear liner production base with annual capacity of 30,000 tons of wear-resistant castings. At the production base, we can produce a variety of wear liners for crushers, grinding mills and vertical stirred mills. Through from casting process design, mold making, smelting & casting, heat treatment, quality inspection, to packaging

Learn More

Resminer Mill Liner - Expert Manufacturer in China - Ware

Resminer is a great choice if you want first-class quality mill liner and wear-resistant products. Our company is very expert in producing high features of grinding media and wear resistant’s including mill liner. We have grinding balls, grinding cylpebs, crusher parts, liner plate, toggle plate, Etc.

Learn More

Grinding Mill Liners | FRASERS

25 Grinding Mills; 25 Abrasive Belt Grinding Machines; 24 Grinding Tools; 23 Grinding Equipment; 23 Tank Liners; 22 Mills; 21 Metal Milling; 12 Tool; Cutter & Drill Point Grinding Machines; 12 Liners Chimney; 12 Profile Milling Cutters; 12 Shoulder Milling Cutters; 12 Paper Mills; 12 Machinery Steel Mills;

Learn More

Mill Liners - Multotec

Mill liners protect the mill shell from wear and transfer energy to the grinding charge. Careful balance is needed to optimise these differing requirements,

Learn More

What Is Mill Relining? - Russell Mineral Equipment

The replacement of the mill liners determines the length of each concentrator shut-down. In other words, the liner lives and their replacement, define the time available for mineral processing. For every hour that the concentrator is shut-down due to liner exchange (Grinding Mill Relining) the mine site asset loses $50K to $500K per hour of

Learn More

Mill Lining Systems | FluidHandling - Trelleborg

Discharge Grates and Mill Lining Accessories. Grinding mills play a key role in comminution and mineral dressing and are subjected to severe impact and abrasion

Learn More

ball mill liner - Magotteaux

These liners are efficient energy wise and make for low grinding media consumption. They can be assessed continuously via profile studies and the design can be

Learn More