optimum angle for toggle plate of jaw crusher | products

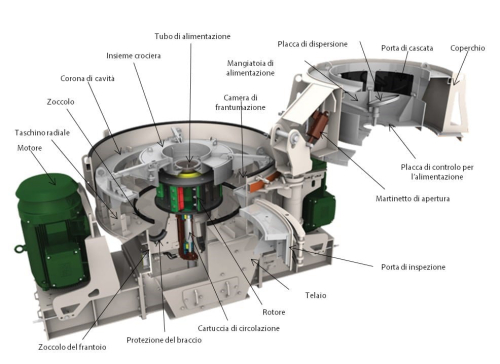

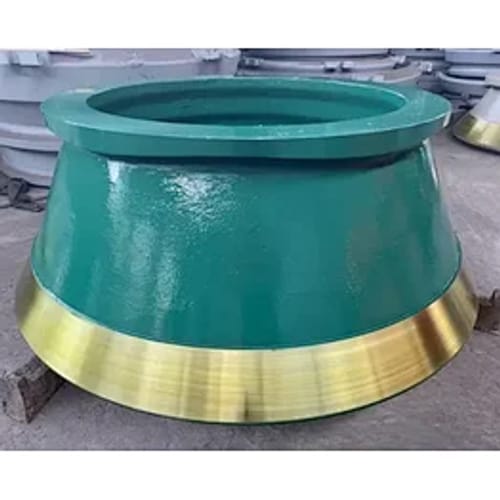

2442 Jaw Crusher; 3042 Jaw Crusher; 3054 Jaw Crusher; 2036 Feeder Screen Jaw Plant; CJ612 4448 Jaw Crusher; Screen Jaw Combo; Cone Crushers. CH660 Hydrocone; CH550 Hydrocone; CH540 Hydrocone; CH440 Hydrocone; CH430 Hydrocone; CS660 Gyrocone; CS550 Gyrocone; CS440 Gyrocone; Closed Circuit Crushing Plant;

Learn More

Basics Of Jaw Crushers - IMS Engineering

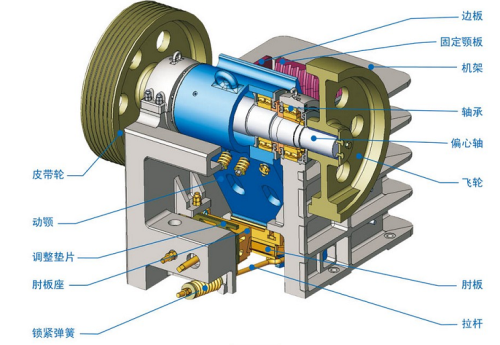

The material's output size can be adjusted by adjusting the gap between the fixed and moving jaw plates. This is known as the closed side

Learn More

PDF) Selected design issues of toggle plate selection on the

The article presents the problem of increasing the performance of the jaw crusher, reducing the crushing power and moment.

Learn More

mj series jaw crushers

Single Toggle MEKA Jaw Crusher is designed for applica- Jaw Crusher. TOGGLE. The optimal-angle toggle plate generates extra crushing.

Learn More

Jaw Crusher Toggle Plate at Best Price in India - IndiaMART

Find here online price details of companies selling Jaw Crusher Toggle Plate. Get info of suppliers, manufacturers, exporters, traders of Jaw Crusher Toggle

Learn More

optimum angle for toggle plate of jaw crusher | WEDGE PLATE 1208

why C Series jaw crushers have a large eccentric throw coupled with a steep toggle plate angle that magnifies the effective stroke at the crusher discharge. The large stroke, combined with the right speed, fly-wheel inertia and high vailable crusher power result in truly high crusher perform-ance.

Learn More

jaw crushers for all your needs - Lutze Process

its size and an ideal nip angle, giving smooth material flow, toggle jaw crusher, characterized A deflector plate at the top of the moving jaw.

Learn More

Jaw Crusher Working Principle - 911 Metallurgist

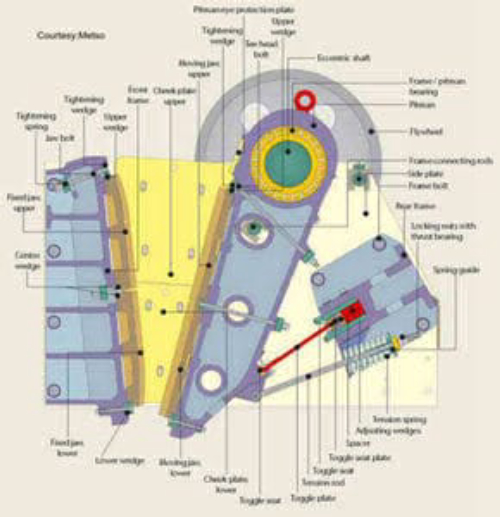

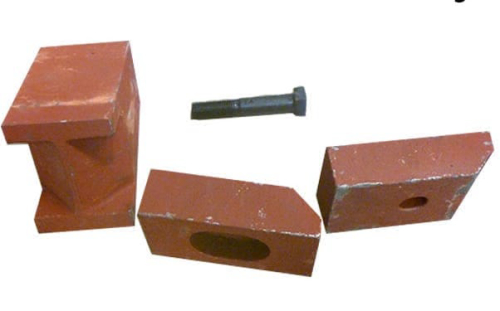

To compensate for we toggle plate, toggle seat, pitman toggle seat, and jaws additional shims must be inserted to maintain the same crusher

Learn More

Jaw crusher - K series - OPT Makine - DirectIndustry

Jaw Crusher - optimal-angle toggle plate, - manganese steel casting side liners, - high-quality shaft and bearings, - and optimal design and quality

Learn More

optimum angle for toggle plate of jaw crusher need a part for a

optimum angle for toggle plate of jaw crusher. Whether it's aggregates, mining, construction & demolition, recycling or road building our jaw, cone & impact crushers are ready for any job. I4C Impact Crusher. 1050mm (41.3") diameter x 1125mm (44.3") wide Impactor; 375Hp (280kW) engine;

Learn More

optimum angle for toggle plate of jaw crusher | crusher spare

Compressive force is applied by two jaws (dies), one of the crusher jaws is Toggle Plate is set at an optimum angle for maximum crushing JAW HEAVY -DUTY crusher hydraulic toggle plate | Pdf Jaw Crusher Toggle Plate. pdf toggle jaw crusher plate bpb35. The Hydraulic Toggle is designed for single toggle or double toggle jaw crushers. read

Learn More

optimum angle for toggle plate of jaw crusher - Gardenseeds

Information Dry mix batching plant adopts concrete mixer truck to mix all materials and produce

Learn More

jaw crusher best jaw plate material composition

Jaw Plate Material and Composition: Jaw Crusher Plate Component Mn14Cr2, When the moving jaw is up, the angle between lining plate and moving jaw

Learn More

optimum angle for toggle plate of jaw crusher

The optimal-angle toggle plate generates extra crushing force and at the same mobile crusher parts dubai structural bushing of the vertical roller mill parts of cone crusher

Learn More

Motion and Force Optimisation in a Single Toggle Jaw

The single toggle jaw crusher is the most common crusher and uses a swing jaw in a Single Toggle Jaw tive function meant that only one optimum angle was.

Learn More

Manufacturing and refurbishing of jaw crushers - RocketCDN

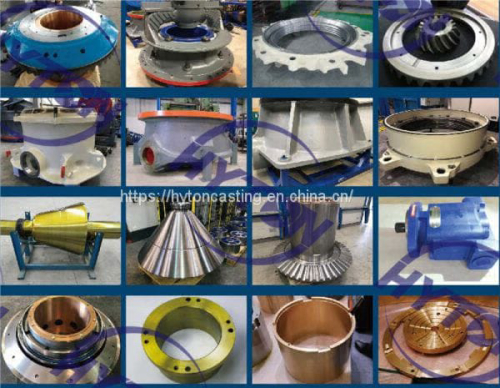

the job since it hardens as it wears during crusher operation. Manganese is also used in the high wear areas at each end of the toggle plates.

Learn More

maintenance for jaw crusher

Jaw Crusher >> E Mail joyal crusherinc >> Http //joyalcrusher Work angle between toggle plate and mobile jaw increases when mobile jaw plate moves up So

Learn More

optimum angle for toggle plate of jaw crusher stone crusher

The JW Series of single toggle jaw crushers is designed with a tight crushing chamber nip angle and an aggressive crushing stroke to maximize productivity. The accompanying table gives typical outputs for our range of machines, based on dry, free flowing material with a crushing work index of 16 and a bulk density of 100 lbs/cu ft (1600 kg/cu m).

Learn More

optimum angle for toggle plate of jaw crusher | turbo shell crusher

Sand steel casting jaw crusher toggle plate manufacturer. sand steel casting jaw crusher toggle plate from Jaw Crushers | McLanahan. A toggle plate and tension rods hold the pitman tight near the bottom of the moving swing jaw. Toggle Plate is set at an optimum angle for maximum crushing. HEAVY-DUTY CRUSHERS. single toggle jaw crushers for

Learn More

optimum angle for toggle plate of jaw crusher | HP4 CNTRSHFT

Pennsylvania Crusher double toggle jaw crushers are superior to both the standard. Jaw Crusher Jaw Plate Standard Sizes. Incorporating a Jaques JW42 jaw crusher and a

Learn More

optimum angle for toggle plate of jaw crusher | stone crusher

Optimum design and analysis of (the) swinging jaw plate of a single toggle jaw crusher. April ; nip angle (angle between swinging jaw plate and . fixed 665 tph Jaw crusher Latvia

Learn More