CNC Machining Copper: Understand the Pros, Cons, and Alloys

Excellent machinability, thermal and electrical conductivity; good corrosion resistance;. Ideally suited to soldering, brazing, and butt welding

Learn More

Detailed Machinability Rating Graph and Chart | A-I-T

372 rows · Have a look at our machinability rating graph which without a doubt will make your decision a lot easier with its incredibly detailed information. Advanced Integrated Technologies

Learn More

The Machinability of Pure Copper

Pure copper has the property of low hardness, high heat conductivity, plasticity, toughness and coefficient of linear expansion. However the machinability of pure copper is bad (about 65% of 45

Learn More

Machinability of pure copper before and after processing by severe

For using ultrafine-grained metals and alloys in industry, further machining sequences and studying their possible effects are necessary to attain these products in their ultimate dimensions. In this work, the machinability of ultrafine-grained pure copper and the corresponding coarse-grained counterpart investigated systematically.

Learn More

What is 'machinability' and how is it measured? - 3ERP

Similarly, copper has a good level of machinability along with characteristics like electrical conductivity. Plastics Thermoplastics can be difficult to machine, as the heat generated by the cutting tool can cause the plastic to melt and stick to the tool.

Learn More

PDF Recommended machining parameters for copper and copper alloysPDF

The excellent machining properties of these copper-zinc alloys is so well-known that they are often used as benchmarks for descri the machining properties of copper and copper alloys Machining copper alloys is considerably easier than machining steels or alumin- ium alloys of the same strength (see Figure 1).

Learn More

Machinability of Copper in Ultra-Precision Micro Diamond Cutting

1989/1/1 · The machinability in micro-machining was discussed from the viewpoints of the chip formation, the cutting forces and the surface integrity of the workpiece. It is confirmed that the continuous chips are formed at a nominal depth of cut of 2.5 nm and the nominal specific cutting resistances increase drastically with a decrease in the depth of cut.

Learn More

Aluminium and Copper - Comparison - Material Properties

The major applications of copper are electrical wire (60%), roofing and plum (20%), and industrial machinery (15%). Copper is used mostly as a pure metal, but when greater hardness is required, it is put into such alloys as brass and bronze (5% of total use).

Learn More

Machinability of ultrafine-grained copper using tungsten carbide

2007/2/1 · The goal of this study is to investigate the machinability of ECAE-processed pure copper using both tungsten carbide (WC) and polycrystalline diamond (PCD) cutting tools in order to facilitate broad applications of ECAE-processed coppers. The results of this work may have application to other similar materials.

Learn More

Analysis of the Machinability of Copper Alloy Ampcoloy ... - NCBI

Analysis of the Machinability of Copper Alloy Ampcoloy by WEDM · 2. Experimental Setup and Material · 3. Results and Discussion

Learn More

Machinability Study of an aluminum-copper alloy

Machinability Study of an aluminum-copper alloy. Borja SANCHEZ ALMIRON (BEng in Aeronautics). Aeronautical Production and Materials Department,

Learn More

What is the machinability of copper?

When it comes to machining, pure copper has poor machinability due to high plasticity and toughness. Alloying the copper with elements such

Learn More

machinability of Copper nickel alloy material - EN 10083-3 alloy steel

machinability of Copper nickel alloy material. Considering the large workload of allocation and transportion for our steel materials, we have built special shipping department, and make it independent form transportation department. The transportation department is in charge of transporting steel materials from our mill and warehouse to the

Learn More

The Machinability of Pure Copper - Yiren Machinery

Pure copper has the property of low hardness, high heat conductivity, plasticity, toughness and coefficient of linear expansion.

Learn More

Copper C101: Properties, Fabrication and Applications

2005/5/11 · Machinability Copper alloy C101 has a machinability rating of 20 when Alloy 360 FC Bras s is 100. Welding of Copper alloy C101 Soldering of Copper alloy C101 is excellent. Brazability and butt welding are also rated as good. Gas shielded arc welding has a fair rating. All other welding processes are not recommended.

Learn More

machinability of copper manufacturers & suppliers

machinability of copper manufacturers/supplier, China machinability of copper manufacturer & factory list, find best price in Chinese machinability of copper manufacturers, suppliers, factories, exporters & wholesalers quickly on Made-in-China.com.

Learn More

Copper CNC machining service - 3D Hubs

Copper is an incredibly versatile metal, making it an optimal choice for producing CNC machined custom parts . The alloy has several useful properties alongside

Learn More

Beryllium Copper Machining - Wonder Copper

Beryllium copper 172 is also non-magnetic and has a very low permeability, making it a suitable choice for magnetic housings. BeCu 172 has a machining cost factor of 3.0 when compared to steel 12L14. It is good for soldering, brazing, forging, welding, and hot and cold working. BeCu 172 can be annealed. Beryllium copper alloy 173 (BeCu) is a

Learn More

An experimental investigation of micro-machinability of copper

by S Filiz · 2007 · Cited by 350 —

Learn More

Machining of Copper and Copper Alloys | Machining | Handbooks

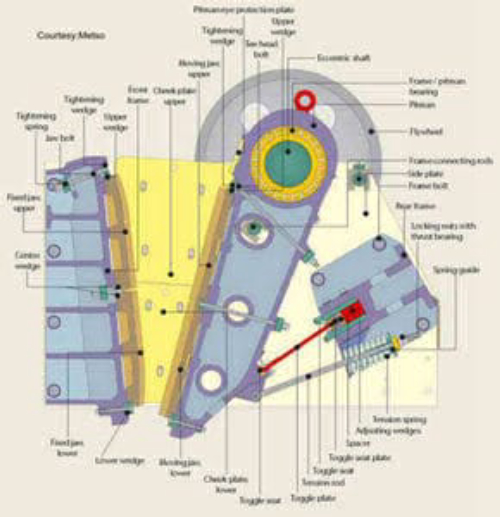

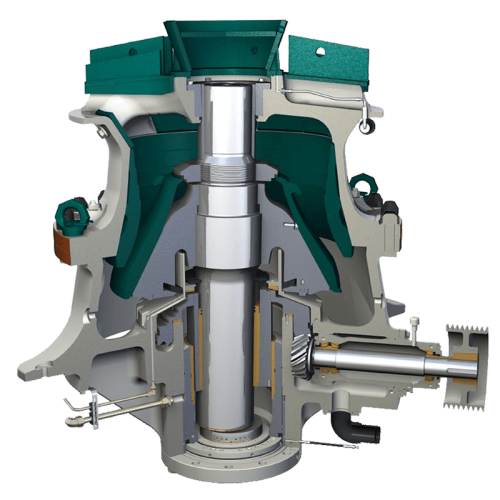

In addition, the article provides a comprehensive discussion on various machining techniques that are employed for machining of copper and copper alloys: turning, planing, drilling, reaming,

Learn More

CNC Machining Copper: Understand the Pros, Cons, and

10/14 · With copper CNC machining, there is also the possibility of formation of built-up edge —which happens when part of the copper workpiece breaks away and is pressure welded

Learn More