Cone Crusher Mantles & Bowl Liners - Optimum Crush

Optimum Crush has the highest quality cone crusher mantle & bowl liners available! Optimize your mining with our custom engineered products.

Learn More

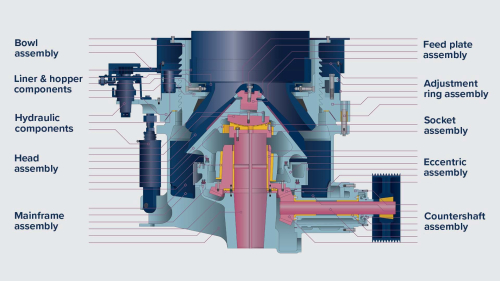

Replacing the liner of a HP cone crusher - Outotec

Jun 09, · A) Mantle - also known as head liner. B) Cutting ring - the cutting ring is not reusable, so a new ring should be installed every time the mantle is replaced. D) Padding

Learn More

Popular Types of Cone Crusher High Manganese Spare Parts

Popular Types of Cone Crusher High Manganese Spare Parts, Find Details and Price about Bowl Liner Cone Crusher Parts from Popular Types of Cone Crusher High Manganese Spare Parts - Zhejiang Hongfei Machinery Manufacturing Co., Ltd.

Learn More

bowl liner for cone crusher | crusher eccentric wearing plate australia

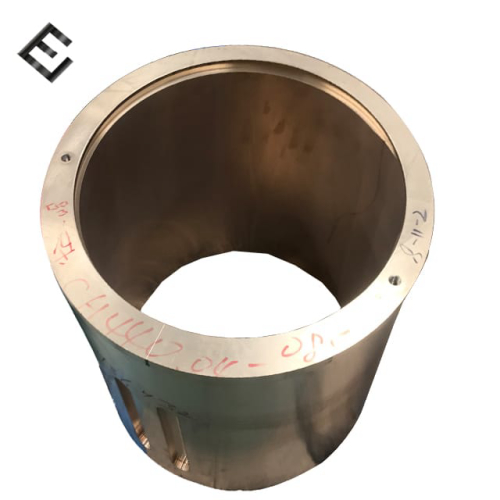

Cone crusher parts : Bowl Liner and Mantle Crusher wear. Cone Crushers for Mining: Cone Crusher Bowl Liners and Mantles for Extreme Conditions Because of the extreme crushing conditions experienced by the crushers used in mining operations, special attention must be paid to the materials used in producing these castings.

Learn More

Cone Crusher Bowl Liner - Victor Bray

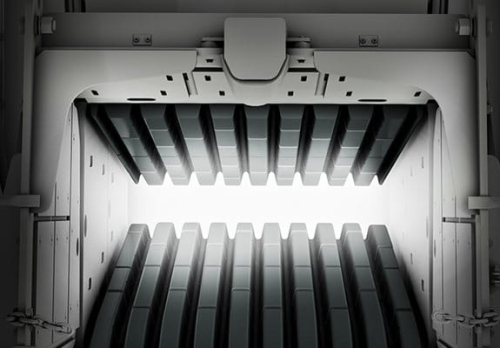

The cone crusher bowl liner is attached at the top of the main shaft. The bowling line fits on the top of the mantle which is also situated at the top of the main shaft. When both the mantle and the concave bowl liner is placed above the shaft they create a space in between them. The materials to be broken are fed in this gap.

Learn More

Buy Wholesale cone crusher bowl liner at Affordable Prices

Get back to mining with wholesale cone crusher bowl liner from Alibaba's vast assortment of mining machine parts from hundreds of manufacturers, suppliers,

Learn More

Crusher Parts Manufacturer Concave Mantle and Bowl Liner Mining Crusher

High Manganese Steel liner Cone Crusher Mantle Bowl Liner Stone Crusher Wear Parts Manufacturer 442.8416 Cone Crusher Wear Parts widely used in mining industry, metallurgical industry, construction industry, chemical industry and silicate industry for crushing hard and medium hard ore and rock, such as river pebble, granite, basalt, iron ore

Learn More

Cone Crusher Bowl Liner, 442.8249 - Pinterest

Qiming Machinery manufactures the aftermarket cone crusher bowl liner (Part number: 442.8249, Weight: 622kg )for the customer who uses the CH430 cone

Learn More

Manganese Mantle Bowl Liner Suit Cone Crusher Wear Parts T900

Hyton produce High manganese casting liners mainly include Mantle, Bowl Liner, Feed Cone , jaw plate, check plate, Arm Liner , Steel Ball ,and etc. Cone Crusher Spare Parts-Cone Concave Advantage and Features. 1. Use: Wear parts for crushers in the quarry, mining, cement, aggregate, recycling, shredding and demolition fields etc. 2.

Learn More

Mn13%,Mn18% bowl liner for 3FT,SH cone crusher

QIRUN MACHINERY For Cone Crusher : 2FT 3FT 4FT 4800 4 FT 5 FT 7FT STANDARD SHORTHEAD Cone Crusher Parts Part Numbers for 3feet OEM FT STD/SH

Learn More

Cone Crusher Wear Parts - Unicast Inc

Durable cone crusher wear parts - bowls and mantles, liners, torch rings, and distributor caps engineered to exceed OEM wear life performance.

Learn More

Bowl Liner - Toughing Crusher

Description Mantle and bowl liner are the main wearing parts for cone crusher. Toughing can manufacture numerous models of concave and mantles for cone crusher. For the material of

Learn More

Mantle Bowl Liner Concave, Cone Crusher Wear Parts | Factory, China

Mantle, Bowl Liner and Concave are the main wear part of Cone Crusher. We provide the matching products according to the customers' machine type. The product mainly uses high manganese steel material, for example Mn14Cr2, Mn18Cr2, Mn22Cr2 and so on. Our cone parts are widely used on mining, construction, chemical, cement and metallurgical industry.

Learn More

MANTLE & BOWL LINER - Precision Casting

And the bowl liner which is also known as cone crusher concave, is the sacrificial wear liner which sets inside the upper frame for protecting the upper

Learn More

Cone Crusher Liners: How to Select and When to Change

If the liner is wearing evenly throughout the chamber, you should consider changing it when it has worn down to about 1” (2.5 cm) thick at the

Learn More

Cone Crusher Bowl Liner manufacturers & suppliers

China Cone Crusher Bowl Liner manufacturers - Select 2022 high quality Cone Crusher Bowl Liner products in best price from certified Chinese

Learn More

HP500 BOWL LINER SH M mark

Bowl Liner Cone Crusher South African. Jaw and cone crusher south africa - mdieticianm jaw and cone crusher south africa crusher machine manufacturer,crushers in south africa 600,000 m2 of production basesy , minzen has built 6 world-class manufacture bases which cover a total area of over 600,000 m 2, and accomplished an annual production

Learn More

Bowl liner Archives - Mayang Crusher Parts

Bowl liner - Mayang Crusher Parts. Video; News; Contact Us; Language. Bowl liner Cone Crusher Parts. Bowl liner, Mantle. Bowl liner YR-0001. Bowl liner, Mantle. Bowl liner YR-0003. Bowl liner, Mantle. Bowl liner YR-0004. Bowl liner. Bowl liner YR-0007. Bowl liner. Bowl liner YR-0008. Bowl liner.

Learn More

bowl liner and mantle parts for cone crusher China Manufacturer

Cone Crusher wear parts manganese casting Concave Mantle . Product information; name: Mantle Applications : Widely used in mining industry, metallurgical industry, construction industry, road building industry, chemical industry and silicate industry for crushing hard and medium hard ore and rock, such as iron ore, limestone, copper ore, quartz, granite, sandstone.

Learn More

high manganese cone crusher mantle and concave bowl liner

high manganese cone crusher mantle and concave bowl liner · 1.The materials use super high manganese steel and alloy high manganese steel, the · 2.Using cold

Learn More

Casting Process And Simulation of Cone Crusher Wear Parts,Cone liners

Cone crusher is widely used in metallurgy, mining, cement and other various industries to break or crush raw material.Cone liners and bowl liners are the mainly replacement parts,In the actual application process,bowl liners have to withstand high intensity of repeated force in a very short time, so the technical of cast bowl liners must be

Learn More